Kraken Update Progress on Subsea Laser Scanner Service Activities

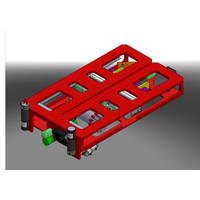

chain inspection for offshore oil and gas infrastructure, and subsea metrology services. In 2022, SeaVision services have delivered over 100 3D models and metrology for offshore wind and oil & gas clients.Kraken is continuing the commercialization of a unique, non-contact SeaVision Mooring Chain Inspection Tool (MCIT). This tool can be used to support existing offshore oil and gas inspection requirements, as well as upcoming offshore wind inspection requirements by providing millimetric accuracy 3D digital twins of critical subsea infrastructure. The SeaVision MCIT is designed to help reduce the cost

Robotics: Collaboration Pushes Boundaries of Offshore Cleaning and Inspection

Woodside collaborated with industry to create a state-of-the-art offshore caisson cleaning and inspection tool (CCAIT system), designed to enable safe and cost-effective remote inspection of offshore platforms.The unique system was designed, developed and deployed in less than 12 months via a collaboration led by Woodside Energy (Woodside) and incorporating Perth-based expertise from Nexxis, Monadelphous, WOMA, and Fugro.The CCAIT system incorporates a human-sized robot, designed to inspect the inside of caissons - vertical carbon steel pipes up to 70m long and up to 1.2m wide. These structures are

Kraken Scores $7.1 Million of Contracts for Offshore Subsea Inspections

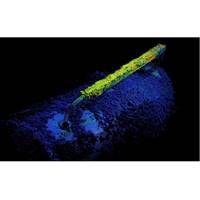

OOGIRA and project partners Cenovus and Suncor. The project avails of joint engineering efforts from Kraken and its recently acquired subsidiary, PanGeo Subsea, leveraging an existing PanGeo sled design with Kraken SeaVision electronics and significant software integration.Example of SeaVision base inspection tool for water column assets (Image: Kraken)Karl Kenny, Kraken’s President and CEO, said, “Over past few years, the term ‘digital twinning’ has become synonymous with innovation in the offshore energy sector, and vital to corporate strategy as operators seek to take advantage

Argeo Taps Eelume 'Snake Robot' for Autonomous Underwater Inspection

carbon footprint and increasing efficiency, Eelume technology will enable Argeo to significantly reduce the costs related to inspection, light intervention and monitoring (IMR) of subsea assets and infrastructure. Currently, 90% of these costs are vessel-related. Implementing Eelume as a resident inspection tool for Offshore Wind and Oil & Gas will replace up to 70% of vessel activities.”Kongsberg has been involved in Eelume since the company was founded in 2015, bringing nearly 30 years of experience from its HUGIN AUV to the development of the Eelume snake robot. “After many years

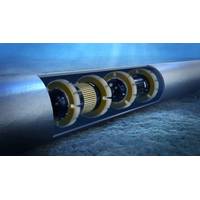

Modus Orders Unique Subsea Pipeline Inspection AUV from Kawasaki

for pipeline maintenance in offshore oil and gas fields. SPICE will be used for operations in the North Sea and other areas around the world after delivery to MODUS in 2021. MODUS has committed to acquiring two units of SPICE AUV from Kawasaki.According to Kawasaki, a robot arm fitted with an inspection tool unit at the end enables SPICE to perform close-range inspections of subsea pipelines not possible with traditional AUVs.In addition, the Japanese company said, the SPICE is operated using a docking station also developed by Kawasaki, which increases inspection operation efficiency and reduces

Pipeline Inspection with Fast(ER) Results

Finland’s Rocsole is hoping to provide operators with better, faster insight into their pipelines through a new compact inline sensor and a large dose of data analytics. Its inspection tool uses electrical tomography and digital signal processing to measure conductivity and permeability values within a pipeline. These are then analyzed to determine the content – fluid and solid – of pipelines or vessels, such as separators.The technology has had the backing of Shell, who are trialling the Deposition In-Line Inspection (DILI) in a 12 in. water pipeline in Brunei in October to detect

Robotics: Autobots Transform in the Offshore Energy Sector

becoming more sophisticated and specialized. Automated pipe handling systems and robotic roughnecks have been introduced to drill floors more recently (OE November 2016: Batteries not included). In the past few years, aerial drones and magnetic hull crawling robots have become part of the offshore inspection tool kit, also mostly with a human operator. In fact, this May saw the first delivery by drone to an offshore vessel (the Pioneering Spirit, in Rotterdam, by Dutch Drone Delta). (More on that here: https://bit.ly/3cWQDuy)Some tentative steps have also been made into topside robotics, from quadrupeds

Wood, NERA Team Up for AI-Powered Subsea Inspections

Oil and gas engineering firm Wood has teamed up with National Energy Resources Australia (NERA) to develop and deliver an AI Inspection tool for subsea oil and gas infrastructure.The companies say that the solution has the potential to revolutionize the way asset inspections are conducted in challenging and high-risk environments across a range of industries while increasing the speed and accuracy of issue detection, response, and resolution.According to a statement released by NERA, Wood’s Augmented Machine Vision Solution provides a real-time inspection device capable of autonomously detecting

Kraken Reports Contracts Worth $2.8 Million

and seamless SAS capabilities. The company expects to provide further details on these new technologies and related products in the coming months.SeaVision Laser ScannerIn collaboration with an international oil and gas company, Kraken’s development of a unique, non-contact mooring chain inspection tool continues, with commercialization scheduled for the fourth quarter of 2020. This tool can be used to support existing offshore oil and gas inspection requirements, as well as upcoming offshore wind inspection requirements. This new platform is anticipated to significantly reduce the cost of

February 2024

February 2024