Fugro Wins $100M Total E&P Congo Contract

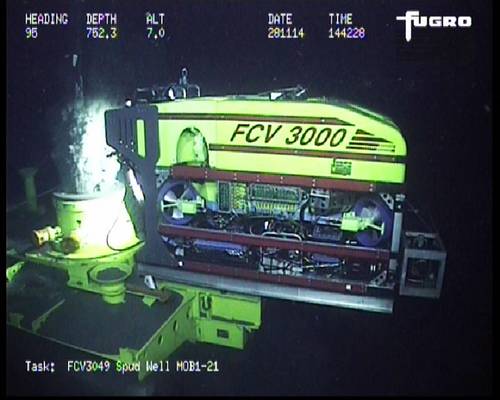

And FCV3000 ROV being monitored from another ROV during the spudding of a new well (photo courtesy of Fugro).

Fugro has been awarded a five-year contract with an estimated value of $100 million by Total E&P Congo. The agreement is for ROV services and remote subsea tooling in the Moho Nord field, situated roughly 75 kilometers off the coast of Pointe Noire in the Republic of Congo.

Fugro will supply four 200hp FCV 3000 work class ROV systems and innovative BOP tooling which will be installed on board three mobile drilling units and one field support vessel.

Three ROV systems have been mobilized from Fugro’s Singapore base and are now operating in Moho Nord. Two of them are on board ultra-deep water drill ships and will be working in water depths of approximately 1,200 meters. The fourth system will be installed on a semi-submersible vessel, which is under construction in China and expected to join operations with later this year.

A central task is subsea BOP intervention and testing, using an ROV equipped with a BOP skid specifically designed for this project by Fugro. Primary responsibility for controlling the BOP lies with the rig, but the ROV operated BOP skids are also used to operate the BOP in accordance with Total’s requirements. When a subsea BOP is installed, various rams are operated and tested on a regular basis under Total’s test procedures. The ROVs also routinely inject glycol into the BOP to prevent hydrate build-up.

“Moho Nord is the first major field in which rig BOP test closures have been carried out using Fugro’s new BOP skid system,” said Richard Mathieson, Fugro Subsea’s ROV services project manager. “This uses a special high-flow pump on the ROV to drive further pumps located on the BOP skid, allowing the transfer of large volumes of water-based fluid from the skid reservoirs into the rig’s BOP hydraulic rams when directed.”

Other ROV tasks include setting up regular fluid injection, drilling re-entry, bulls eye checks and routine video monitoring, inspection, cleaning and intervention tasks on and around the BOP, as well as alignment control during manifold installation. The ROV on board the field support vessel recently installed transponder arrays on the seafloor to accurately position the drill ship at its drilling location.

February 2024

February 2024