A new magnetic sledge introduced by Oslo-based Miko Marine is capable of retrieving ferrous objects as small as a fingernail from underwater.

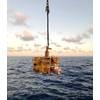

Measuring two meters by one meter, the sledge is made from aluminum and equipped with 10 permanent magnets. When towed over the seabed, the sledge can pick up objects that may be covered by sand or silt and achieve results that would be difficult or impossible for divers to equal, said Miko Marine, a salvage technology company that has particular expertise in the use of magnets.

Each magnet is suspended independently beneath the sledge from a flexible mount that enables it to pass over rough or broken ground without damage or becoming snagged. Capable of working at any depth, the sledge can be equipped with a video camera and an acoustic positioning system such as a Sonardyne Scout linked to a GPS chart plotter. This enables it to follow an accurate search pattern and ensure that nowhere is missed. The sledge is typically fitted with buoyancy to offset the weight of the magnets so it can be handled efficiently and for the height at which it is towed above the seabed to be precisely controlled.

The Miko magnetic sledge is a potentially useful tool for police and accident investigations. One was recently used to successfully recover parts from a Super Puma helicopter that crashed into the sea near Bergen, Norway in April. The aircraft went down with the loss of two crew and 11 passengers during a flight from the Statoil Gulfaks-B platform. It went into relatively shallow water close to the shore near Turoey and subsequently caused the world’s fleet of Super Puma helicopters to be grounded until the cause of the accident is known.

Although much of the wreckage was quickly recovered, accident investigators were anxious to study the helicopter’s transmission. The Accident Investigation Board of Norway consequently commissioned Miko Marine to design and build a sledge that could be used to recover ferro-magnetic debris hidden beneath the seabed around the crash site.

Responding to the urgency of the request, Miko engineers were able to design, build and deliver the sledge within four days.

The sledge was operated from a 12-meter workboat catamaran that surveyed an area of seabed measuring some 400 by 700 meters, working 12-hour shifts over a period of two weeks ending on May 20. By the end of the search a number of metal objects had been recovered for analysis including the vital components from the helicopter’s transmission system.

February 2024

February 2024