SafScan: High Definition Laser Surveying

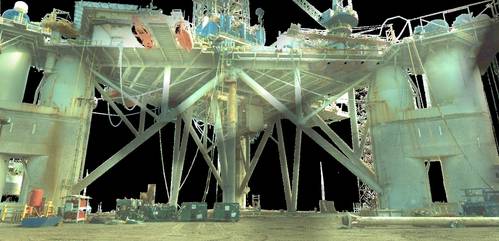

Safway is introducing SafScan High-Definition Laser Surveying, which it said can deliver very accurate, precise three-dimensional (3D) images of existing conditions at any industrial plant, offshore facility, bridge or other commercial site. Instead of relying on out-of-date drawings or estimated measurements to engineer and plan projects, Safway’s SafScan technology creates a precise, as-built copy of any jobsite using state-of-the-art laser scanning equipment. Safway claims to be the first and only access and industrial service company to provide clients with such an effective time and cost-saving service.

“SafScan provides a level of precision that is nothing short of amazing,” said Jerry Dolly, manager of the Bridge Division at Safway. “By improving accuracy through the collection of one million data points per second, we are able to engineer projects based on a totally reliable, solid foundation of information. This allows us to plan, order equipment and materials, and schedule labor to improve overall job performance, safety and efficiency.”

After the point-cloud data (a 3D coordinate system of points measured by SafScan) has been gathered, Safway’s engineers can begin planning a comprehensive solution for the job. Whether its new pipe modeling for a pipe rack project or taking detailed I-beam or tank measurements so that scaffolding and platforms can be built-to-fit before any equipment arrives on the jobsite, SafScan provides a head start that can save valuable time and money by avoiding interferences and retrofits. No industry is beyond the scope of SafScan, from bridges, commercial properties and historical renovations, to boilers, and oil/gas or petrochemical refineries. The opportunities for project improvement and workflow are enormous.

Custom solutions utilizing SafScan’s equipment, services and resources include 3D drawings/models, site/plant documentation, project planning, sections and elevations, “clash” detection and clearances. By taking advantage of Safway’s complete array of access and industrial services including SafScan High-Definition Laser Surveying, time and cost can be saved, while quality, performance and safety are enhanced.

safway.com

February 2024

February 2024