Underwater Thruster Installation Stays on Schedule

Two and a half months after Hydrex diver/technicians removed the bow thruster of a 363-meter container vessel in Rotterdam, a Hydrex team once again mobilized to reinstall the overhauled unit underwater with the use of the Hydrex flexible mobdock technique.

Like the removal, the operation was performed in stages at several locations to allow the vessel to keep to its sailing schedule. The superintendent of the ship was very happy with the first part of the operation. For this reason the customer asked Hydrex to take care of the reinstallation as well. The job was completed well within the available time frame thanks to good team work of the ship staff and the Hydrex divers.

The available time window was very short for the ship. The time required to reinstall the thruster unit therefore needed to be brought back to the absolute minimum. For this reason the operation was split in parts. The first part of the procedure was carried out during the vessel’s stop in Le Havre.

Installing the bow thruster unit in Le Havre

We have a special R&D department that is continuously looking for new ways to streamline the repair procedures used by our teams. One of the results of their research his a cradle designed especially for thruster operations. This device allowed the Hydrex divers to lower the bow thruster unit into the water in Le Havre and maneuver it inside the thruster tunnel in one take.

Another technology developed by Hydrex in-house are our mobdocks used to close off a thruster tunnel. Mobdock is short for ‘Mobile mini drydock’ because they enable our diver/technicians to create a dry environment to work in, while the vessel stays afloat. These mobdocks have been used during thruster operations for 20 years now. Initially rigid mobdocks were used, but later a lightweight flexible variant was designed and put in use. These can be shipped to anywhere in the world by plane very fast.

After all water was removed from the tunnel, the team secured the unit and connected it to the engine room.

This finished the first part of the operation. The divers returned to the Antwerp headquarters, ready to mobilize again when the vessel was arriving at the Port of Rotterdam.

Phase two of the operation carried out in Rotterdam

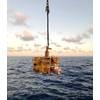

Deployment to Rotterdam was done using one of the Hydrex workboats loaded with all the needed equipment. The Hydrex catamarans are fully equipped as dive support stations that can be used for a wide range of operations. They increase flexibility of operation. This is essential during operations like these where speed is of the utmost importance.

In Rotterdam the team once again used the lightweight mobdocks to close off the thruster tunnel on both sides. Once this was done they installed the thruster propeller blades one by one. With the thruster blades in position, the ship left Rotterdam on schedule.

February 2024

February 2024