J+S Subsea Delivers Control Systems for Canadian Oil and Gas Project

Subsea controls specialist J+S Subsea has completed its first project in Canada, which involved the supply of three subsea battery-powered control systems to maintain integrity of the subsea electrical infrastructure at an offshore oil and gas field.J+S Subsea systems will maintain integrity of the subsea electrical infrastructure when topside electrical power is unavailable, the company said.The project has been delivered through a collaborative approach involving Viper Innovations, Verlume, Richmond Mills Fabrication and MH Engineering (Fife), as well as J+S Subsea.The scope included the design

Dana Petroleum Hires Subsea7 for North Sea Field Job

development. We look forward to supporting Dana in meeting their project objectives and for the opportunity to play a key role in the safe and successful completion of Bittern,” said Steve Wisely, Senior Vice President of UK and Global Inspection, Repair and Maintenance, Subsea7.The Bittern oil and gas field is located in Blocks 29/1a and 29/1b, 22km south-east of the Triton FPSO.The field was discovered in 1996 and has been developed through five production wells and two water injection wells via a subsea tie-back to the Triton FPSO. First production was in April 2000.A number of well interventions

ClassNK Offers Guidelines for ROV/AUVs

ClassNK produced "Guidelines for ROV/AUV” which summarize the performance and safety requirements for remotely operated underwater vehicles (ROVs) and autonomous underwater vehicles (AUVs).To date, ROVs and AUVs have been mainly used for oceanographic surveys and offshore oil and gas field development, but in recent years their utilization as a means for maintaining offshore wind power generation facilities and pipelines has been steadily increasing. Although the utilization of ROVs and AUVs is increasing worldwide, no international standardization of such technologies has yet

IEV Wins Subsea Pipeline Inspection Gig in Malaysia

the contract through its 49%-owned associate, IEV Malaysia.Under the contract awarded by an unnamed oil and gas producer IEV Malaysia will be providing an ultrasonic scanner technology deployed by a remotely operated vehicle (“ROV”) to inspect a subsea pipeline located at an offshore oil and gas field in Malaysia. he contract is estimated to have a contract value in excess of US$1.5 million (approximately MYR6.47 million).IEV said Monday that equipment and personnel preparation and mobilization had already started. Offshore work is planned to be undertaken within the next few months

First Subsea Installations Begin at Duva

and construction campaign for the Duva field development is now underway with the installation of the Integrated Template Structure (ITS), Neptune Energy said on social media on Tuesday.The ITS is the first large scale piece of fabrication work to be completed for the Neptune Energy-operated Duva oil and gas field in the northern part of the North Sea, Norway. Weather conditions permitting, it is expected to be installed over the course of a five-day campaign, the London-based independent oil company said.According to Neptune Energy Norge’s Managing Director Odin Estensen, "By installing the

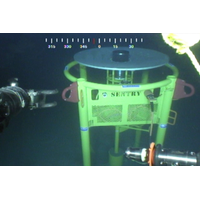

Leak Detection Sonar Deployed in the US Gulf

, has been deployed on the seafloor at more than 2,000 meters water depth. The ROV-deployable Sentry IMS, which features a titanium housing and can be installed short-term or permanently, is able to detect, classify and localize subsea releases of hydrocarbons from either the seafloor or oil and gas field production infrastructure, its developer said.In this latest deployment, Sentry is being deployed under a six-month trial that will demonstrate its ability to provide real-time subsea asset monitoring. The Sentry sonar head, which is mounted on a seafloor lander, is connected into an existing

Kvaerner to Study Floating Wind Structures

of the five Snorre A and B, and Gullfaks A, B and C platforms. In periods of higher wind speed this percentage will be significantly higher.Kvaerner, which provides the full scope of engineering, procurement, construction and installation (EPCI) services for both fixed and floating platforms for oil and gas field developments, said it has identified offshore wind as one of the company’s main growth areas in the coming decades. Today, Kvaerner said it offers fixed and floating substructures in steel and concrete as well as converter platforms for offshore wind farms.“During the FEED period

Equinor to Build CO2 Storage Under the Seabed

around the time of the breakthrough Paris climate change agreement in 2015.But environmentalists say is a costly technology that will perpetuate the status quo when rapid and deep cuts to energy use are needed to limit global warming.The planned storage will be located near Norway's largest oil and gas field, Troll, and aims to be able to receive CO2 from onshore facilities, such as power or cement plants, to reduce emissions to the atmosphere.Equinor and partners Shell and Total are working on front-end engineering and design (FEED)-studies, which should provide more accurate cost estimates.The

Tidal Power for Seabed Oil and Gas Installations

operations as green as possible.Successful testA prototype Power Hub, using one turbine, completed a successful eight-month sea trial in December 2017 at the European Marine Energy Center (EMEC) in the Orkney Islands, northern Scotland. EC-OG is now refining the system to match the requirements of oil and gas field developers. These include having two or more turbines and differing battery sizes depending on site requirements.The device being lowered to the deck of the Leask Marine C-Odyssey workboat, in preparation for installation at the European Marine Energy Centre (EMEC). (Photo: Nortek)EC-OG is

August 2024

August 2024