ABS Guidance Notes: Design Methodology for Dynamically Installed piles

ABS has published Guidance Notes that includes the first industry best practices on design methodology for dynamically installed piles. The new ABS Guidance Notes on Design and Installation of Dynamically Installed Piles provides a better understanding of the geotechnical and structural performance of piles, enabling engineers to develop safe and efficient pile designs.

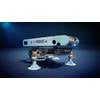

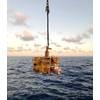

Dynamically installed piles are finned piles designed to be released from 20 to 100 m above the seabed and reach velocities from 20 to 25 m/s before self-embedment. The tip penetration is expected to be two to three times the pile length with holding capacity after consolidation ranging from three to six times the pile weight. By referring to the Guidance Notes, engineers are able to minimize uncertainties using methodology that incorporates strain rate and inertia drag for pile design and installation.

“With installation and procurement costs for conventional foundation technologies increasing with water depth, dynamically installed piles become a more attractive option,” says ABS Chief Technology Officer Howard Fireman. “Our role at ABS is to use the results of our research to help industry understand deployment considerations fully so installations can be carried out more safely.”

Ken Richardson, ABS Executive Vice President, Global Offshore, adds: “A deeper understanding of pile performance will permit safer installations, which will facilitate the wider use of dynamic piles in deep water. This is why ABS developed the industry’s first Guidance Notes to address this issue.”

The Guidance Notes presents best practices for geotechnical design, structural assessment and installation of dynamically installed piles and includes a method for calculating pile embedment depth in cohesive soil. Engineers using the Guidance Notes have access to useful tools to meet the design criteria specified in the ABS Rules for Building and Classing Offshore Installations, the ABS Rules for Building and Classing Floating Production Installations and the ABS Rules for Building and Classing Mobile Offshore Drilling Units.

February 2024

February 2024