European Wave Energy Project Gets $4.4M Funding Boost

seven European countries, strategically chosen for their world-leading capabilities and knowledge.Partners include leading universities National University of Ireland Maynooth and Technical University of Denmark, OEMs FibronPipe and LESER, specialist SMEs Julia F. Chozas, Applied Renewables Research, Marine Systems Modelling, the offshore test site PLOCAN, and wave energy technology developer Wavepiston.The choice of the Wavepiston technology ensures practical applicability and provides a reference framework for the development of key components, enabling comparability of results, benefiting not only the

Kraken Robotics Appoints Adu as Head of Services Business

Kraken sales team, is based in the Middle East, and will be focused on European and NATO markets," Kraken said.Dennis Hogan has joined the US Sales Team and based out of the Boston office. Before joining Kraken, Hogan served as the Commercial Sales Manager – North America for Klein Marine Systems from 2019 to 2023. Specifically, he handled sonar sales and account management for commercial, defense, and law enforcement clients. Prior to that position, Mr. Hogan had held positions in product management, marketing, and technical sales for marine electronics manufacturers Navico

NOAA Awards Contracts for Uncrewed Marine Systems Data Services

$22.5 million.IDIQ contracts allow the agency to streamline the processing and delivery of commercial products and services from industry vendors. The selected vendors—Saildrone, Chance Maritime Technologies LLC, Ocean Power Technologies, 1stMission LLC and XOCEAN—will use their uncrewed marine systems to collect data for NOAA missions and provide that data to NOAA as a service over a three-year period from September 2023 through August 2026.The awarded contracts will cover services provided under three NOAA mission areas living marine resource surveys and research, meteorological and oceanographic

MIND Technology Sells Klein Marine Systems

MIND Technology, Inc. sold its Klein Marine Systems unit for $11.5 million to General Oceans, Inc., a subsidiary of General Oceans AS. Pursuant to the transaction, MIND has licensed its Spectral Ai software suite to General Oceans for certain applications, particularly side-scan sonar. MIND and General Oceans have also entered into a collaboration agreement for the further development of Spectral Ai and potentially other software projects. The transaction closed August 21, 2023.Klein has served the offshore mapping and defense industries for over 50 years and will strengthen General Oceans'

MIND Technology earns MA-X Technology Patent

MIND Technology said that the U.S. Patent and Trademark Office granted a patent for MA-X technology. MA-X was engineered and designed by MIND's Klein Marine Systems unit and is an integrated single beam side scan and gap filler sonar.MA-X provides imaging of the nadir zone, or "gap", with the same interpretive characteristics of side scan sonar reportedly improving survey times by up to 40%. Klein's first product incorporating this technology is the MA-X VIEW 600. This system delivers focused 600kHz imagery (which is comparable to 900kHz resolution) with 100% bottom

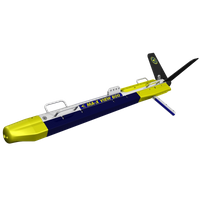

Kraken Wins $50+ Million Contract for Royal Canadian Navy Minehunting

of Combat-variant and Training-variant mine disposal systems (MDS), transportable command center (TCC) and Computer-Based Trainer (CBT).Kraken’s partners on this program include Kongsberg Maritime Canada Ltd., provider of HIl’s Mission Technologies Division’s REMUS AUV, thyssenkrupp Marine Systems Canada Ltd (tkMS), providing their SEAFOX mine disposal vehicles, and SH Defense who will provide the containerized multi mission module system “The Cube” as transportable command center and effector/ launch and recovery center.Formal contract signature and kickoff of the Acquisition

Exail's DriX USV Gets Lloyd's Register Certification

energy companies worldwide and has already received Bureau Veritas Approval in Principle (AiP).The new certification attests that the surface drone meets critical safety requirements to be operated at sea. The DriX system design was reviewed against the Lloyd’s Register Code for Unmanned Marine Systems.It included a detailed system level analysis, construction survey, as well as sea trials. The review covered essential design area such as structural integrity, stability, as well as command and control in the context of remotely supervised autonomy.This new certification by Lloyd’s Register

Kongsberg Sets Up Renewables Tech Business

and roll out renewable energy in a big way. The company will strengthen Kongsberg's existing investments in offshore wind as well as add new capabilities," Kongsberg said."Kongsberg is already a significant player in offshore wind and has domain and technology expertise in areas such as marine systems, marine operations, energy management, seabed- and environmental mapping and monitoring, as well as digital solutions for monitoring and managing industrial processes. The establishment of Kongsberg Renewables Technologies will further strengthen the group's technology development and domain

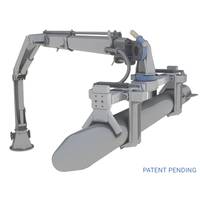

FMD, DECK Strike Deal to Co-Develop 'Intelligent' LARS

Fairbanks Morse Defense (FMD), a portfolio company of Arcline Investment Management (Arcline), is expanding its capabilities to serve unmanned marine vehicles (UXV) through a licensing agreement with DECK Marine Systems (DECK), a developer of systems to deploy and recover vessels and sensors. Through the agreement, FMD and DECK will co-develop an intelligent launch and recovery system (LARS) for use with UXVs, and FMD will have an exclusive license to sell and service DECK’s LARS, instrument deployment units (IDUs) and winches for the U.S., Canada, Australia and UK government markets.

February 2024

February 2024