Dyneema

- Equipment, Machinery & Materials-Ropes - Woven, Wire & Mooring

Locations

Office Europe, Middle East and Africa

The Netherlands

Americas Offices

South Stanley NC 28164

United States

- Phone: 800.883.7404

Americas Offices

Ivy St Mesa AZ 85205

United States

- Phone: 704.862.5000

Office Latin-America

São Paulo 717

Brazil

- Phone: +55 11 3046 3350

Office Asia - Pacific

Singapore 638928

Singapore

- Phone: +65 6908 0550

Dyneema® is the world’s strongest and lightest fiber. It’s 15 times stronger than steel on a weight for weight basis and 40 times stronger than aramid. Yet it can float on water. This combination of extreme strength and low weight make it suitable for a wide and expanding number of applications.

The huge range of uses include:

Super strong yet light mooring ropes, crane ropes, and aquaculture nets

Cut-resistant protective gloves and high-strength threads for medical applications

Bullet-resistant vests and highly advanced anti-ballistic vehicle armor

Fuel-saving lightweight airplane cargo nets and containers

High performance clothing, shelters, footwear, backpacks, and sports equipment

- Web: http://www.dsm.com/

Products

Product Technologies

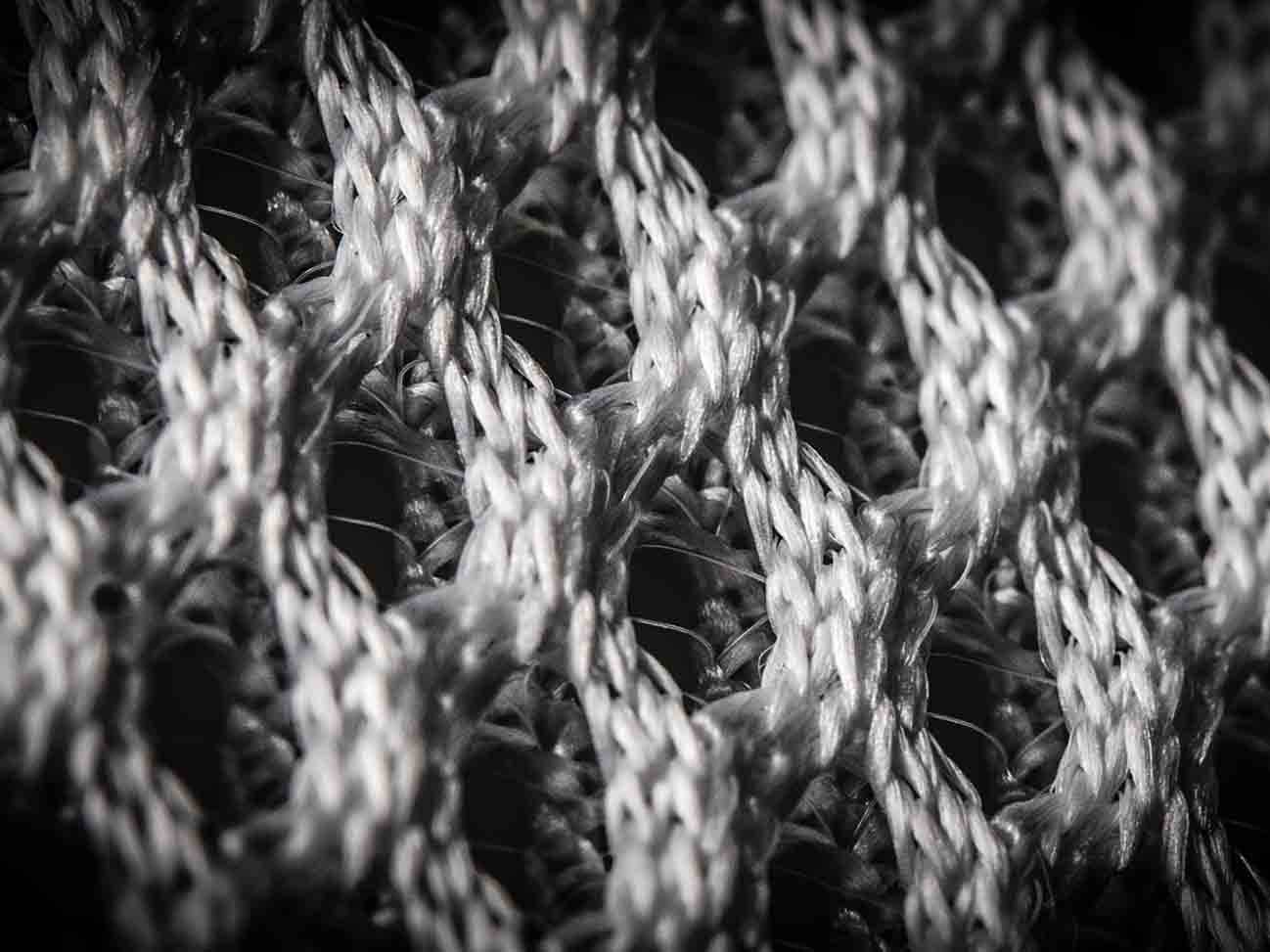

Dyneema® is a super-strong fiber and tape made from Ultra-High Molecular Weight Polyethylene (UHMwPE). The combination of extreme strength and low weight makes it suitable for a wide and growing range of applications.

The secret to UHMwPE’s superior performance lies in the extremely long molecular chains that transfer load more effectively to the polymer backbone. As a result Dyneema® is 15 times stronger than steel on a like for like basis. In fact, UHMwPE has the highest impact strength of any thermoplastic made today. Yet it can float on water.

UHMwPE doesn’t smell, doesn’t taste of anything, and it is nontoxic. It is highly resistant to corrosive chemicals and shows extremely low moisture absorption. It’s also self-lubricating, highly resistant to abrasion, and its friction coefficient is significantly lower than that of nylon, for example, and comparable to that of polytetrafluoroethylene (PTFE, Teflon) – but with better abrasion resistance.

Documents

• Mooring the world’s largest cruise ships is safe and simple with ropes made with Dyneema® - When the world’s two largest cruise liners currently afl oat make their brief stops at ports around the Caribbean, mooring ropes made from the world’s strongest fi ber hold them fi rmly in place. Outstanding strength coupled with low weight and great ease of handling are the key reasons why Royal Caribbean Cruises Ltd. (RCCL) chose ropes with Dyneema® for the Oasis of the Seas and the just-launched Allure of the Seas.

Products

Dyneema® Fiber

UHMwPE

Dynamica SK78 – Rope made with Dyneema

Dynamica SK78

Dyneema® Fabrics

Dyneema® Tape Technology

Dyneema® Crystal Technology

February 2026

February 2026