Royal IHC, Shanghai Salvage Ink Reel Lay System Deal

the client’s new build vessel during the first quarter of 2020, followed by sea trails. Dave Vander Heyde, CEO Royal IHC: “We are very proud to have been selected by Shanghai Salvage as their partner for this innovative pipelay system due to our strong track record for sophisticated pipelay systems. IHC has been active in the Chinese market for over 30 years, delivering dredging vessels, dredging equipment and multiple offshore systems like pipelay systems and AHC deep water lowering systems. This new contract with Shanghai Salvage further strengthens our position in this important market

Huisman is Keeping Very Busy in Schiedam

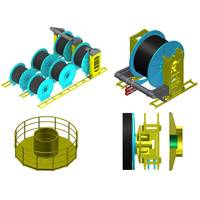

Huisman, a worldwide specialist in lifting, drilling and subsea solutions, currently has five new built pipelay systems out on the quayside of their production facility in Schiedam, The Netherlands. These “high five” showcase the latest in pipelay technology and underline the added value of the new production hall for Huisman Schiedam. This 66m high production hall offers the largest indoor lifting capacity in Europe (1,200mt), allowing for the simultaneous indoor assembly, including testing and commissioning, of several products and systems. This allows for fast installation, commissioning

Huisman Banks 10 Pipelay Equipment Orders

Huisman, a worldwide specialist in lifting, drilling and subsea solutions, has secured new contracts for 10 pipelay systems with various major offshore pipelay contractors. The new contracts include three 550mt Tiltable Lay Systems (TLS) and one 325mt Vertical Lay System (VLS) for Subsea 7, two 650mt TLS and two 340mt VLS for Technip-DOF, one 275mt VLS and one 570mt Multi-lay System for Ceona. The equipment will be built at the various Huisman production facilities in The Netherlands, Czech Republic, China and Brazil. Delivery of these pipelay systems is scheduled between the end of this year and

Ecosse Subsea Systems Prepares to Shake Up Pipelay Sector

success of Ecosse’s SCAR subsea trenching plough, which has exceeded performance targets and established the company as an innovator which can transcend both the traditional oil and gas sector and the emerging renewables market. Traditionally rigid pipelay projects rely on very expensive pipelay systems which are embedded into dedicated and sophisticated vessels which command hefty hire rates in the region of £250k plus per day. These large systems require extensive deck strengthening on the vessel and the systems usually take a minimum of 14 days to install, more normally the major components

February 2024

February 2024