A New Standardization for Subsea Forgings

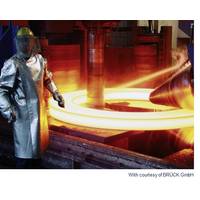

Steel forgings are essential building blocks for subsea components, but tailor-made solutions to meet end-users’ specific requirements have caused long delivery times. A joint industry project (JIP), led by DNV GL, has now taken the next step in subsea standardization by harmonizing requirements for quality management of forgings. The recommended practice (RP) ‘Steel forgings for subsea applications – quality management requirements’, DNVGL-RP-B202, will enable delivery of high quality forgings at reduced delivery times and cost. Complementing the RP ’Ste

ABS Approves First Subsea's Large Scale Steel Forgings

Subsea mooring specialist, First Subsea, has achieved American Bureau of Shipping ABS 2009 Approval for its larger R4 steel forgings up to 562mm diameter. These are the largest diameter forgings to have received the approval, and set the benchmark for Offshore Mooring Accessories with forged bars to the requirements of ‘ABS Guide for Offshore Mooring Chain (2009)’, section 1.9 Special Subsea Mooring Connectors. The ABS 2009 Certification of Offshore Mooring Chain (updated 2014) specifies the requirements for materials, design, manufacture, and testing of offshore mooring chain and

DNV GL Targets Reduced Subsea Lead Times

Steel forgings are important building blocks for subsea components and are often tailored to meet end-users’ specific requirements. This results in long delivery times and repeated follow-ups throughout the supply chain. With DNV GL’s new Recommended Practice (RP) ’Steel forgings for subsea applications’ these requirements are now harmonized. The implementation of the RP will enable reduced lead times, enhanced stock keeping, interchangeability of forgings and help to improve and maintain consistent quality. “Unifying requirements for forgings into an acceptable

Aberdeen Subsea Section for DNV GL

to standardise and streamline efficiency issues in the subsea industry. A recent cooperation project related to subsea documentation seeks to present a minimum unified set of documentation requirements for all major subsea components. Another current project addresses common specifications for steel forgings. Bert Droy, Business Development Lead for Subsea and Floaters in Aberdeen concludes: “Having a dedicated section for subsea, with clear guidelines from which they can draw, is good news. Meetings are planned with our DNV GL peers globally, and the outcome will reinforce how we

New Subsea Equipment Certification Standards from DNV GL

underway to standardize and streamline efficiency issues in the subsea industry. A recent cooperation project related to subsea documentation seeks to present a minimum unified set of documentation requirements for all major subsea components. Another project addresses common specifications for steel forgings. Benefits of the new standard and certification scheme With this new standard and certification scheme, DNV GL seeks to drive improved quality, reduce costs and help in the delivery of projects on schedule. More specifically, the standard will: •Provide a predictable set of documents

New DNV JIP to Speed Up Subsea Construction

One challenge in the construction of a subsea project is the long delivery time of large steel forgings used for key components. This is mainly due to compliance with oil companies’ individual requirements. DNV is now inviting the subsea industry to jointly obtain synergies by developing a best-practice approach. The aim is to reduce delivery time and production costs and improve material quality, thus reducing the risk throughout the supply chain. Due to quality concerns, the end users of subsea systems are stipulating company-specific requirements for subsea forgings, such as those used for

First Subsea - Receives ABS 2009 Approval

from steel grade 4330V forgings up to 510mm outside diameter. The subsea mooring connectors can be used with R3, R3S, R4, R4S & R5 grade chain and shackle. Leader in Large Scale Forgings Research The ABS 2009 Approval builds on First Subsea's investment in research into large scale steel forgings. In collaboration with the University of Sheffield's Institute for Microstructural and Mechanical Process Engineering (IMMPETUS), the company leads the world in research into the manufacture and testing of 4330V large scale steel forgings. The company's research was instrumental the development

December 2025

December 2025