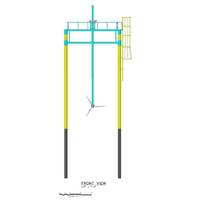

Tidal Energy Test Site Installed in Cape Cod Canal

the winch that will power the lifting member that turbines will be attached to. The structure is now secure in the water off the Railroad Bridge and the U.S. Army Corps of Engineers’ Cape Cod Canal Field Office. The structure was built in Middleboro, Mass. by MassTank, manufacturer of steel tanks and large structures for all sorts of applications including marine and heavy industrial uses. The next step for the test site will be to install the data acquisition, processing and transmission system atop the platform. Engineers from Impact Labs will work in the weeks to come

US Tidal Energy Test Site: Installation Set for Next Week

tidal cycle in both directions, enough to turn different types of tidal turbines to test their efficiency, power output, robustness and more. Turbines of up to 3 meters can be tested with vertical lift provided for easy access. The structure was built at MassTank by experienced manufactures of steel tanks and large structures for various applications including marine and heavy industrial uses. The Bourne Tidal Test Structure is part of the New England Marine Energy Development System (NEMEDS), a network of testing facilities located within a 100 mile radius that aim to help device designers

ULSTEIN PX121 for Otto Offshore

for four vessels. These PX121 vessels are capable of supporting offshore activities which are being carried out further from shore and in deeper waters. The vessels can carry flexible loads. In addition to tanks for various contents such as oil, water, and drilling fluids, they have four stainless steel tanks for flammable liquids or corrosive chemicals (LFL tanks). The vessels are certified by DNV and carry the ‘Clean Design’ notation. Measuring 83.4 m long with a beam of 18 m, they have a cargo deck of 840 sq. m. and a load capacity of 4,000 tons (dwt). Each ship has a maximum speed

Two More PSVs for Vroon

metres and a load capacity of 4,200 tonnes (dwt). Thanks to flexible tank capacities, the PX121 is set up to support drilling activities with longer and deeper boreholes and activities further from shore. In addition to tanks for oil, water and drilling fluids, the vessel also has two stainless steel tanks for flammable liquids or corrosive chemicals. Each ship will be equipped with dynamic positioning system Class II and meets the requirements of ‘Clean Design’, according to ABS class. The PX121, which has a maximum speed of approximately 15 knots and modern accommodation for 23

Ulstein Delivers PSV

. Blue Thunder measures 83.4 x 18 m, and is designed for a maximum speed of approximately 16 knots. It has a load capacity of 4,200 tons (dwt), and the 850 sq. m. cargo deck can carry a deck load of 2,200 tons. In addition to tanks for oil, water and drilling fluids, the vessel has four stainless steel tanks for flammable liquids. Blue Thunder has modern accommodation for 23, and is equipped with a dynamic positioning system IMO class II and meets the requirements of DNV’s Clean Design notation. (As published in the June 2013 edition of Marine Technologies - www.seadiscovery.com

Ulstein Delivers Fourth PSV in PX121 Series

of 83.4 meters and a beam of 18 meters, and keeps a maximum speed of approximately 16 knots. She has a load capacity of 4,200 tons (dwt), and the 850 square meter cargo deck can carry a deck load of 2,200 tons. In addition to tanks for oil, water and drilling fluids, the vessel has four stainless steel tanks for flammable liquids. Blue Thunder has modern accommodation for 23 persons, she is equipped with a dynamic positioning system IMO class II and meets the requirements of DNV’s Clean Design notation. Ulstein Power & Control has delivered the electrical systems on board, including

August 2025

August 2025