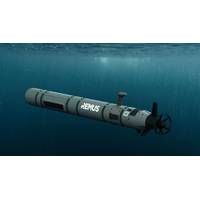

HII Delivers REMUS 620 UUVs to NOAA

requirements with rapid development and deployment of new capabilities and technology.”The REMUS 620 vehicles provided to NOAA feature advanced modular design and engineering enhancements. These custom modifications include a synthetic aperture sonar module, an additional energy module, and auxiliary equipment specifically for NOAA’s underwater mapping and habitat restoration projects.NOAA intends to utilize these REMUS 620 UUVs primarily for high-resolution mapping in the Gulf of Mexico. A key focus will be on restoring Mesophotic and Deep Benthic Communities—dark, sunless seafloor

UCO Grows Saab Seaeye Falcon ROV Fleet

across all sectors which will see it provide a range of services in Europe, North America and the Middle East.In addition, UCO has made significant investment in additional equipment and now holds a stock of £250,000 dedicated Saab Seaeye Falcon spares and more than £350,000 worth of auxiliary equipment ranging from manipulators to station holding and everything in between.UCO has enjoyed year-on-year growth since entering the market in 2017 through expansion of its range of services and global sphere of operations. In particular, it specialises in the development of innovative solutions

NOAA Orders Two REMUS 620 UUVs

underwater vehicles (UUVs) from HII.The customized, medium-class UUVs will be built by HII’s Mission Technologies division in partnership with W.S. Darley & Co. and delivered in 2024. The vehicles will be customized with a synthetic aperture sonar module, additional energy modules and auxiliary equipment.NOAA will use the REMUS 620 vehicles for higher-resolution mapping of the Gulf of Mexico and its effort to restore the seafloor habitats damaged by the 2010 Deepwater Horizon oil spill. The agency has previously used other REMUS models for habitat characterization, marine archeology and other

KIGAM Orders New Research Vessel

sampling.The vessel has been designed to include a variety of installed equipment, such as a 3D/4D seismic eight-streamer system, high resolution 2D/3D seismic P-cable system, a multicomponent OBN acquisition system, a Marine Gravity and Magnetic system, Multibeam and Single beam echosounders and auxiliary equipment for in sea acoustic sounding systems. Further, the vessel incorporates a Deep Sea Chirp Sub-bottom profiler, an Acoustic Doppler Current Profiler (ADCP) and a High profile Underwater Positioning system. Sediment samplers and geochemical analysis equipment are available for the on-board researchers

New Harbor in the Island of São Miguel (Azores)

by the local Municipal Authority of Povoaçao wascarried out with the objective of promoting nautical tourism in this area of the island as well improving conditions for local boaters. The execution of the design, manufacturing and installation of the floating pontoons and the supply of auxiliary equipment have been carried out by Lindley.The facility comprises of pontoons and fingers from Lindley’s ‘Sagres’ range manufactured with a galvanized and painted steel structure, ideally suited for the challenging conditions of these Atlantic islands. Access to the floating facility

Revolutionizing Deepwater Drilling Riser Buoyancy

increase the overall hydrodynamic diameter of drill riser buoyancy modules and therefore VIV suppression comes without the undesirable penalty of increased in-line drag. Obtainable VIV mitigation properties of the inverted tri-helical buoyancy design with the elimination of required auxiliary equipment simplifies and increases the running and retrieval times of the riser compared to traditional suppression technology. Numerous locations across the globe are subject to the sudden onset of onerous weather, requiring drilling vessels to be able to respond quickly in order to transit out of

Foster Wheeler Wins Contract For Retrofit-SCR System

, chemicals and petrochemicals, power, minerals and metals, environmental, pharmaceuticals, biotechnology and healthcare industries. The company’s Global Power Group is a world leader in combustion and steam generation technology that designs, manufactures and erects steam generating and auxiliary equipment for power stations and industrial facilities and also provides a wide range of aftermarket services. The company is based in Zug, Switzerland, and its operational headquarters office is in Reading, United Kingdom. Foster Wheeler website : www.fwc.com.

Claxton Wins its Biggest Riser Contract Offshore Norway

, an Acteon company, has been awarded a multiyear contract with Det norske oljeselskap ASA of Norway: the largest single riser contract in Claxton’s history. Running from January 2014 until June 2020 (with optional periods of 1+1 year), the contract includes high- and low-pressure risers, auxiliary equipment and services offshore Norway. The scope of work includes the procurement of high and low-pressure surface risers for the lvar Aasen field development; the rental of a Claxton 18.3/4”, 7,000 psi subsea riser for the Hanz field; the rental of 18.3/4”, 15,000 psi high and 30&rdquo

HB Rentals Completes Renewable Energy Contracts

over 200 people. Broken down, a supply vessel operating in the Prinses Amalia Windpark has received five, 32ft four person sleepers. The remaining modules have been deployed on platforms and jack-up barges situated in the Borkum West II field. The projects also included the provision of auxiliary equipment such as conference rooms, recreation facilities and sewage treatment plants as well as all design, engineering, project management, installation, hook-up and commissioning services. As part of the projects HB Rentals has carried out modifications on all modules prior to delivery to ensure

February 2025

February 2025