GeoSphere: Mapping-while-drilling Evolution

of the reservoir structure. When it comes to steering, the GeoSphere service detects individual layers in horizontal sections radially—as mentioned earlier—more than 100 ft [30 m] from the wellbore, exceeding the formation coverage of conventional logging-while drilling technologies. Combined with surface seismic data, this amount of zonal coverage gives geoscientists and drilling engineers the capability to extend laterals—even in the most complex geological settings—within the sweet spot. As for mapping, the GeoSphere service maps the reservoir

Forum Delivers 350th RT Torque Machine

rotational torque and provides an auditable report for thread inspectors, drilling contractors or casing crews. After delivery, Forum will provide TAM with maintenance and support from equipment specialists in Aberdeen and Singapore. James Bement, Forum’s Senior Vice President of Drilling Technologies, said, “Our equipment has gone through many improvements over the past 27 years, and our 350th machine provides customers with the latest software to meet the increasing demand on make-up inspection criteria. Among other improvements, our new hydraulic power unit (HPU) is capable of

Sakhalin-1 Sets Another Extended Reach Drilling Record

also protect the environment by minimizing areas involved in drilling and production operations. Rosneft Head Igor Sechin said: “This well continues successful implementation of our outstanding project. I would like to express my thanks to our partners – ExxonMobil. Usage of their drilling technologies made this achievement possible”

Schlumberger Unveils UltraHT Drilling Technologies

Schlumberger announced today the launch of TeleScope ICE* ultrahigh-temperature measurements-while-drilling service and PowerDrive ICE* ultrahigh-temperature rotary steerable system (RSS). These new technologies enable standard drilling operations in reservoirs with extreme temperatures, expanding the applications and the range of the field-proven PowerDrive* RSS and Scope* measurement services. “In high-pressure, high-temperature (HPHT) projects, customers are under intense pressure to manage costs and achieve drilling objectives. This is particularly challenging because HPHT environme

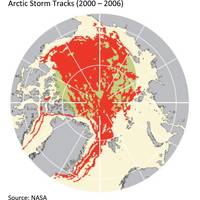

An Open Arctic and its Impact on Oil Drilling

William Cho, Head of MatthewsDaniel Weather, a division of the Bureau Veritas Group, explains why improvements in drilling technologies and weather monitoring systems have made offshore shelf drilling operations in the Arctic Circle increasingly attractive to upstream oil and gas companies and their investors. Rising crude oil prices motivate not only technological innovators to explore cheaper alternative energy sources, such as solar panels and wind turbines, but also upstream oil and gas companies to explore new oil reserves which had not otherwise been economical. While the exact amount is less

Aker Solutions Starts Trading After Company Split

of the former Aker Solutions, which has been split into two separate entities to reduce complexity, realize synergies and bring down costs. The other company formed in the separation is Akastor, an oilfield services investment business that will develop the former group's other units, including Drilling Technologies. "The split creates a simpler and more focused Aker Solutions that is better positioned to meet the needs of customers in an increasingly competitive global energy industry," said Luis Araujo, chief executive officer of Aker Solutions. "We will build on our leading positions

Shell Tests Off-Site Rig in Office Backyard

and gas resources that lie there. As many remaining resources are trapped tightly in rock pores or located thousands of metres beneath the seafloor, new techniques are needed. These must be both safe and cost-effective. New techniques A team of Shell engineers is continuously trialling new drilling technologies. Usually these would be tested in the field. But this has the disadvantage of stopping usual operations and incurring costs. To avoid wasting time in the field, Shell engineers work on a unique rig – the only full-scale one of its kind for testing. It stands among the low-rise office

Demerger Proposed at Aker Solutions

Solutions, the existing Aker Solutions ASA will change its name to Akastor ASA to form the Akastor Group together with the other subsidiaries that have not been transferred to New Aker Solutions. The Akastor Group will, among other things, continue Aker Solutions' activities mainly related to drilling technologies, process systems, surface products and Aker oilfield services, as well as business solutions, some financial assets and real estate. On completion of the demerger, consideration shares in New Aker Solutions will be issued to the shareholders of Aker Solutions. Each share in Aker Solutions

Aker Solutions to Divide Company in Two

areas will form a new company under the Aker Solutions name. The company will be more strategically aligned, have a narrower focus and deeper synergies to strengthen its leading position through its unique subsea technology and state-of-the-art offshore field design. The other units, including Drilling Technologies, Aker Oilfield Services and Process Systems, will be developed independently as part of a new oil-services investment company, named Akastor. These business areas, which have significant operational, technological and commercial differences, will have greater strategic freedom to develop

February 2025

February 2025