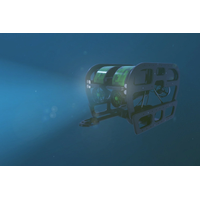

NASA and bp Collaborate on Space and Subsea Visualization Technology

underwater or millions of miles away on another planet.The initial phase of the agreement will focus on developing standards and expanding the capabilities of visualization and simulation models. Later phases could include the exchange of remote operating practices, including safety, communications, process control and monitoring, integrity management, predictive analytics and artificial intelligence.bp hopes this Space Act Agreement with NASA will help advance energy production on Earth, as well as human exploration of the Moon, Mars and beyond.The agreement could lay the foundation for future collaborations

SWiG's Wireless Acoustic Standard to Improve Comms Between Offshore Vessels & Subsea Vehicles

companies.The JIP, SWiG says, creates space for industry players to work together on technical matters related to subsea wireless technologies.Shreekant Mehta, Senior Vice President, Energy Sector at Sagentia Innovation, says the SWiGacoustic specification is geared towards activities such as process control, monitoring, diagnostics, and maintenance. By improving these areas, it has the potential to enhance the overall performance of subsea operations. “Subsea vessel and vehicle operators use various wireless technologies, from radio-frequency and acoustic to inductive power and data

Balmoral Tanks Appoints Lockwood, Tsang

and raised from an early age in Scotland, Tsang received his BSc in production engineering and management from Strathclyde University and, from there, has followed a career in engineering and manufacturing. Mr Tsang has held various management and directorial roles in design/development, quality/process control, production and operations and has worked extensively in the UK, China and Germany

Sonardyne Acquires Chelsea Technologies Group

Group Ltd. as part of a long-term growth strategy that includes market diversification.In acquiring Chelsea (also known as CTG), Sonardyne said it looks to strengthen its presence in the maritime, marine and ocean science sectors and create new opportunities in the water environmental, defense and process control markets. Chelsea will gain access to Sonardyne’s considerable research, production, testing, compliance and global distribution capabilities, allowing the company to access many more international territories.Chelsea, based in West Molesey, Surrey, has a broad base in environmental sensing

Kongsberg Wins Johan Sverdrup Phase 2 Contract

will also extend and modify already delivered systems for the field center, in addition to providing three Subsea Production System tie-backs and technology solutions for shore power at Haugsneset, near Haugesund.The core scope of supply for Johan Sverdrup phase 2 features SAS technology including Process Control, Subsea Control Unit, Power Distribution Control, Process Shutdown, Emergency Shutdown, Fire & Gas systems, Life Cycle Simulator, Information Management System and OPC-UA data gateway. The latest generations of Kongsberg Maritime SAS technology for production, integration, presentation,

Powering the Seafloor: Put a Socket in It

be eliminated completely by also moving chemical storage and injection subsea, and even having local power generation for power needs (ENI is working with a wave energy buoy firm on such a concept) and using wireless communication.DataThere’s also another benefit to going all-electric: greater process control and condition monitoring capabilities, and the potential to leverage big data. “Electric systems are inherently more instrumented than hydraulic systems, so you have better knowledge and predictability, and availability and you can further reduce system cost,” says Lundanes.Electric

CTG Introduces New Non-contact Algae System

A new Algae-Station Non-Contact system from water quality sensor designer Chelsea Technologies Group (CTG) will be launched at Sensing In Water (UK) on September 27-28 and WEFTEC 2017 on October 2-4. The Algae-Station NC provides water process control operators with a unique monitoring system which reduces cleaning and maintenance requirements that are commonly associated with in situ sensors, reducing cost of ownership of these type of sensors, CTG said. These non-contact systems, up till now only available for such parameters as turbidity and flow, are now, with the Algae-Station NC

Greensea Adds Wingart as Quality Control Engineer

Greensea has appointed Kevin Wingart as Quality Control Engineer. In this role he will lead the company's quality control department and is primarily responsible for designing and implementing methods for process control and quality assurance. Prior to joining Greensea, Wingart worked as a principal engineer for ERIN Engineering and Research where he performed probabilistic risk assessment for nuclear power plants. Wingart served four years in the U.S. Air Force as an Information Technology Specialist and one year in the Peace Corps as a renewable energy technology transfer volunteer. He

BIRNS Invests in New Automated Molding Press

firepower to the company’s molding facility for connector inserts, allowing computer controlled precision for functions like injecting glass reinforced epoxy (GRE) and providing increased speed and output for large orders. The press has an advanced user interface for seamless set up and process control, offers the options of either manual or fully automated cycles, and features multiple zone heat control, with closed loop thermocouple connections on the system used for monitoring precise mold temperature. Control transfer pressure, velocity, time and position provide the exact transfer profile

August 2025

August 2025