Underwater 3D Printing of Concrete Ready for DARPA Assessment

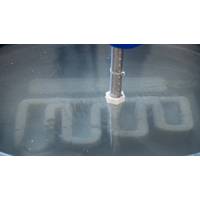

Since it was invented in the 1980s, 3D printing has moved from the laboratory to the factory, the home and even outer space.Now, an interdisciplinary group of Cornell researchers is developing a way to bring the technology to the ocean. By 3D-printing concrete underwater, the new approach could transform on-site maritime construction and the repair of critical infrastructure that connects continents.“We want to be constructing without being disruptive,” said Sriramya Nair, assistant professor of civil and environmental engineering in the David A. Duffield College of Engineering, who leads

ErectorCraft Launches First 3D-Printing Boat Hull Firm in US

methods.Beyond its flagship 3D-printed hulls, ErectorCraft delivers a range of services designed to drive marine manufacturing forward.These include the sale and integration of ErectorBot LFAM HDPE systems, specialized engineering and production optimization, and the deployment of 3D concrete printing (3DCP) technologies for marine construction applications.ErectorCraft also provides training and technical support to help partners seamlessly adopt this next generation manufacturing process.“With its official launch, ErectorCraft is not just introducing a new way to build boats — it&rsquo

Subsea Tech: Taking 3D Printing to the Seabed

where internal corrosion is a common issue. PTTEP of Thailand has been our partner through the development of the Nautlus, and will also be the pilot client for introducing the service in the region, says Carlsen.In tandem with commercialising the composite repair system, has been working on adding 3D printing to Nautilus’ capabilities and has recently joined forces with Equinor, SINTEF and Gassco, with Norwegian National Research Council funding and support from part-owner-incubator Kongsberg Innovation to make this happen. Just like the composite repairs, the process would be done inside the

Subsea 3D Printing Tech Targeted for 2022

Norwegian robotics company Kongsberg Ferrotech has joined forces with Equinor, SINTEF, and Gassco to develop 3D printing technologies for subsea equipment repair and maintenance.The company has already developed a subsea robotic system, Nautilus, that can be used to carry out remotely operated composite repairs on subsea pipelines.Now the Kongsberg Ferrotech wants to add additive printing capability to these systems, using metallic media to repair defects, with support from the Research Council of Norway through the PETROMAKS 2 program. The company will use 3D printing to rebuild damaged metal structure

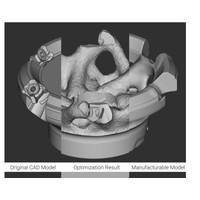

The Case for 3D Printing Downhole Tools

Advanced design software supports growth of additive manufacturing applications in the oil and gas industryAdditive manufacturing (AM, aka 3D printing) is beginning to impact product-development strategies in the oil and gas industry just as it already has in many other industries—by shifting the production paradigm in unexpected ways.Particularly in the case of downhole tools, overall tool size is compatible with the range of part dimensions that today’s AM systems are capable of manufacturing. Consider a common piece of equipment on any oil and gas rig: the tricone drill bit. Required to

TMS to Use 3D Printers for Submarines

thyssenkrupp TechCenter Additive Manufacturing (in Mülheim an der Ruhr, North Rhein-Westphalia), the required technology and expertise will now come to the Kiel Fjord. It is planned to complete the transition by June 2020.Dr. Luis Alejandro Orellano, COO of thyssenkrupp Marine Systems said: "3D printing opens up completely new potentials for us. In the design engineering, we no longer have to consider the limits of conventional manufacturing processes everywhere. In this way, we give our customers more freedom in the design of the boats."Orellano added: "At the same time, we can produce

World First: Patrol Vessels Deploy 3D Printers

3D printing technology developed in Darwin will be deployed by the Royal Australian Navy in a world-first trial that will streamline the maintenance of patrol vessels.The Morrison Government will invest $1.5 million in the two-year Supersonic Deposition 3D printer pilot, which will lead to a significant increase of parts availability compared to what the regular supply chain can provide.Minister for Defense Industry, the Hon Melissa Price MP, congratulated the Charles Darwin University’s Advanced Manufacturing Alliance, along with industry partner SPEE3D, for producing the cutting edge and

Thyssenkrupp Wins 3D Printing Approval

The international accredited registrar and classification society DNV GL has awarded thyssenkrupp, German multinational conglomerate, first additive manufacturing approval of manufacturer certificateThe shipping industry is looking to take advantage of additive manufacturing (AM), also known as 3D printing, to print spare parts, thereby reducing lead times, costs, stock requirements, and environmental impacts. Certification ensures that AM part users can have the same confidence in an additive manufactured product as a conventionally produced one.The newly issued certificate makes the thyssenkrupp

December 2025

December 2025