Teledyne Marine Pays Tribute to Doug Webb

key role in the development of Vertical Current Meters (VCMs) to measure water chimney convection and profiling floats (ALACE). He commercialized this development (APEX) which became part of the ARGO program. He invented and developed the Teledyne Slocum gliders.Webb pioneered the development of the buoyancy systems used in these floats and gliders, revolutionizing how scientists approach ocean data gathering. Argo is the most successful ocean observing program, contributing critical information about climate and sea level change.Webb was also honored by Rutgers University’s undergraduate class of

Balmoral Develops In-Line Mooring Buoyancy for Offshore Wind and SURF Applications

solution.“Our in-line mooring solutions are designed in accordance with all relevant industry standards, while we have also worked hand-in-hand with clients to deliver their third-party approved designs across a number of projects.“As they are provided in modular fashion our mooring buoyancy systems can be configured to suit specific project uplift requirements.”According to Balmoral, in-line mooring buoyancy benefits are:•Lower number of components and connections•Increased reliability with fewer potential failure points•Reduced risk of wear•Decreased dynamic

Lander Lab #3: Buoyancy

. We all love the shrunken Styrofoam cups, but that just shows the poor bulk modulus of Styrofoam.Closed cell rigid polyurethane foams: General Plastics (Tacoma, WA) offers marine grade rigid foams in a range of densities and depth ratings, engineered for shallow to mid-water subsea buoyancy systems. Densities range from 12-lbs/ft3 with test depth of 300-ft (92m), up to 25-lbs/ft3 with a maximum test depth of 1,200-ft (366m). The material has high impact resistance, and is biologically inert. Standard sheet sizes are 10” x 24” x 100”, and 14” x 18” x

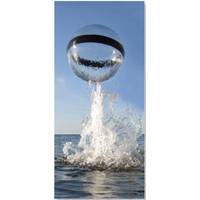

Creating Superior Buoyancy with Air

Testing When choosing a supplier for buoyancy for remotely operated vehicles, manufactures should look for a company that not only manufactures hollow glass microspheres but can also carry out testing of density, strength, moisture content and more, before the HGMS are incorporated into composite buoyancy systems. Following this, the finished buoyancy package should then go through its own testing to ensure the final product meets the density, weight and strength parameters for the project. Typical buoyancy tests that should be performed on the final package include: Hydrostatic

OceanWorks Upgrades Italian Navy ADS

OceanWorks International says it has carried out a major system upgrade of the Italian Navy’s Atmospheric Diving Systems (ADS). Taking advantage of thruster improvements and upgraded electronic systems, the enhancements to the HARDSUIT System are focused in two main areas; Thruster and buoyancy systems Electronics and communications systems Oceanworks explains that it capitalized on the improvements in performance and reliability of subsea thruster systems by developing a proprietary subsea thruster power unit. To accommodate the change in physical configuration and weight distributio

Seaflex Bouyancy Shows Real Utility

Unique Maritime Group’s marine buoyancy solutions help stricken vessel and world’s largest windfarm; highlights the diverse uses for Seaflex buoyancy systems. Unique Maritime Group, one of the world’s leading integrated turnkey subsea and offshore solution providers, today announced two key projects, involving buoyancy systems provided by Seaflex Ltd. World’s Largest Offshore Windfarm The London Array is an offshore wind farm under construction in the outer Thames Estuary in the United Kingdom. With 1,000 megawatt (MW) capacity, it is expected to

February 2026

February 2026