PSW Technology Nets 'Sizable' Deepwater BOP Stack Services Contract

quarter of 2023. Scana said the contract was a sizable one, meaning it is worth between NOK 10 million (currently at $970,865) and NOK 50 million (currently around $4,85 million).Scan said that the contract showed PSW’s "unique" expertise and services related to well control and drilling equipment for the rig market, where the company has, over the past 15 years, collaborated with international drilling contractors on the maintenance of subsea and drilling equipment.Geir Knapskog, interim Managing Director of PSW Technology said: “The offshore rig market shows strong signs of recovery

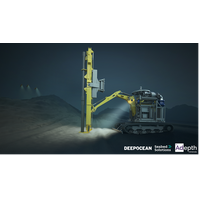

Norway: Funding Granted for Deep-sea Mineral Core Sampling Tech

of OilThe FlexiCore will be mounted to the “Seabed Excavator”, an existing electric, crawling, flexible and powerful subsea tool carrier designed for deep-sea operations down to 4,000 meters and has previously completed projects at 3,200 meters. The Seabed Excavator and FlexiCore drilling equipment are electrically powered and remotely controlled from an offshore service vessel.Adepth Minerals expect that the FlexiCore will be used for data collection related to the exploration and evaluation of the mineral potential on the Norwegian shelf.“Our ambition is to provide more data through

Offshore Equipment Firm Dril-Quip Names New CEO

Offshore drilling equipment specialist Dril-Quip, has named Jeffrey J. Bird as its new President and Chief Executive Officer. Effective as of January 1, 2022, he'll replace Blake T. DeBerry, who will step down at that time. DeBerry will continue to serve as Chief Executive Officer and as a member of the Board until December 31, 2021.John Lovoi, Dril-Quip’s Board Chairman, said:"On behalf of the Board, I would like to thank Blake for his superb stewardship of Dril-Quip as CEO and as a Board member over the past 10 years and for all of his contributions since joining the Company in

Silicon Sensing Upgrades Gyro for Downhole Surveying

. This upgrade of Silicon Sensing’s established CRS39 gyro includes a move to a single board from two. This has reduced the unit’s mass by 40% and allows it to be installed far more easily in space-limited applications, such as the 25mm diameter cylinders typically used in downhole drilling equipment.CRS39A also incorporates upgraded micro electro-mechanical systems (MEMS) and electronics, including new drive electronics and improvements to the sensor head. These have delivered significant performance enhancements in critical areas such as bias instability, angle random walk, noise and

Enhanced Drilling Tech for Vår Energi's Ops Offshore Norway

Norwegian oil and gas company Vår Energi has signed a framework agreement with drilling equipment firm Enhanced Drilling.Under the agreement, Enhanced Drilling will provide Vår Energi with its Cutting Transportation System (CTS) and Riserless Mud Recovery (RMR) services on Vår Energi operated fields.According to Enhanced Drilling, headquartered in Straume just outside of Bergen, Norway, the RMR system ensures all mud and cuttings are returned to the rig, with zero discharge to the sea. "The result is a safer and more stable top-hole, drilled with minimal environmental impact.

New Tech Simulates Methane Hydrate Recovery

from MES-HD and Fukuoka University simulates multiphase flows inside lifting pipes, which allows consideration of the dissociation of shallow methane hydrate and can also be applied to the gas lifting method.The lifting simulation aims to assist in the design of various devices including seabed drilling equipment, lifting pipes, and gas processing equipment onboard resource recovery vessels. It will also enable support for the safe and efficient operation of shallow methane hydrate lifting equipment and gas processing equipment.(Photo: MES-HD)MES-HD said it has acquired various hydrate-related technologies

Op/Ed: Connecting to the Future of Offshore

120 miles out at sea, 6,000-horsepower devices lift drilling equipment weighing up to 3 million pounds out of holes lying 10,000 feet beneath the water. Keeping such sea monsters in good working order, often for years at a time, is no mean feat. Oil companies spend between $300,000 and $800,000 per day on each vessel drilling offshore. Any failures can result in losses that run into hundreds of thousands of dollars per day.With such high costs and massive market pressures, including volatile oil prices, increasing competition and operations in complex environments, offshore companies are seeking new

Obama Administration Bars New Oil, Gas Exploration off Alaska

competitive disadvantage." Russia and Norway have also explored the Arctic, though Exxon Mobil wound down drilling in the Russian north in 2014 due to U.S. sanctions over Moscow's aggression in eastern Ukraine. Fierce winds and frigid waters make the Arctic treacherous for drilling equipment. After spending billions of dollars to explore the Alaskan Arctic, Royal Dutch Shell retreated in 2015 after suffering a gash in one of its ships and environmentalists had uncovered details of an old law that forced the company to cut exploration there by half. The U.S. Coast Guard

U.S. Offshore Oil Drilling Rule Planned

The United States is planning to impose a major new regulation on offshore oil and gas drilling to try to prevent the kind of explosions that caused the catastrophic BP Plc oil spill in the Gulf of Mexico, the New York Times reported on Friday, citing Obama administration officials. The Interior Department could make the announcement as early as Monday, the paper said. It is timed to coincide with the five-year anniversary of the BP disaster, which killed 11 men and sent millions of barrels of oil spewing into the gulf. The rule is expected to tighten safety requirements on blowout preventers

August 2025

August 2025