Putting Power on the Seabed: Edging towards a Subsea Powerhouse

and offshore wind would need subsea control systems, and this is something ABB is also working on.Photos from ABBSiemens close to qualifiedAnother JIP was run by Siemens Energy to deliver 6 MVA of power over 200km and distribute it locally, is ongoing. Supported by Chevron, Exxon, Equinor, and Eni Norge (now Vår Energi), Siemens Energy is adding a VSD (now at TRL4), switchgear and controls to its already qualified transformer, all for 3,000 m water depth.Siemens’ entire subsea power distribution grid, including VSDs, transformer, switchgear, and control, all in oil-filled pressure

Digitization of the Norwegian Continental Shelf

A new web-based tool is being used for the first time offshore for collecting, systematizing and presenting safety critical information on the Goliat platform in the Barents Sea.The system, developed by Eni Norge in cooperation with Safetec and SINTEF, measures and monitors more than 10,600 technical components in real time.The solution reflects several years of intensive work in the industry to develop better methods and systems for risk management. Since 2013, Eni Norway with design and engineering support from Safetec and SINTEF, and software development of Eigen Ltd, has developed a

Johan Castberg PDO Approved

spinoffs.Equinor and the other operators with oil deposits in the Barents Sea are looking at the possibilities of oil transfer at Veidnes in Finnmark county, including both a downscaled terminal solution and ship-to-ship transfer.The Johan Castberg partnership consists of Equinor (operator 50 percent), Eni Norge (30 percent) and Petoro (20 percent)

WIN WIN: Wind Powered Oil Recovery Concept Progresses

that wind power could be used to power offshore water injection. The project is currently moving into its second phase, which includes refining and testing the electrical systems, and investigating possibilities for broader applications. The project consists of four partners: DNV GL, ExxonMobil and ENI Norge – all part of the first phase – and the Norwegian Research Council – a new participant for this second phase. The first phase of the project determined the concept is technically feasible, capable of meeting performance targets, and cost-competitive with conventional water

Norway's Rising Subsea Stars

, announcing an innovative solution designed to both help the environment as well as the profitability of the beleaguered oil and gas industry: Wind-Powered Oil Recovery. Specifically the plan is designed to use floating wind turbines to power a water injection system. JIP partners include ExxonMobil, ENI Norge, Nexen Petroleum UK Ltd., Statoil, VNG Norge, PG Flow Solutions and ORE Catapult. “We can now see renewable energy as a large scale source of power to offshore oil & gas operations. By using the recent developments of floating offshore wind turbines this concept can offer a clean

Wind-powered Oil Recovery Project Green-lighted

renewable and oil and gas industries have worked together in the DNV GL-led WIN WIN (wind powered water injection) JIP to develop the concept of using floating wind turbines to power a water injection system in detail and assess its technical and commercial feasibility. JIP partners include ExxonMobil, ENI Norge, Nexen Petroleum UK Ltd., Statoil, VNG Norge, PG Flow Solutions and ORE Catapult. Technical and operational aspects as well as costs have been assessed, and no major challenges have been identified through the JIP’s study. Analyses of system performance examining site specific

Eni Starts Production of Goliat Field

for Eni’s growth strategy and will significantly contribute to the cash flow generation. In the Production License 229, Eni holds a 65% stake (operator), while Norway's Statoil holds the remaining 35%. Eni has been present in Norway since 1965, where it operates through its subsidiary Eni Norge AS. In the country, the company has interests in exploration licenses and production fields, including Ekofisk, Åsgard, Heidrun and Kristin with a total equity production in 2015 of 106 thousand barrels of oil equivalent per day

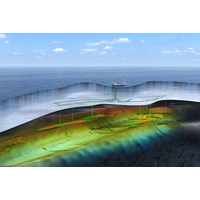

Aker Delivers World's First Subsea Compression System

near the wellheads, rather than on a platform, improves recovery rates and reduces capital and operating costs. Subsea compression also leaves a smaller environmental footprint and is safer to operate than a platform. The Åsgard field's operator is Statoil and license partners are Petoro, Eni Norge, Total E&P Norge and ExxonMobil E&P Norway. Aker Solutions has supported Statoil on installation, testing and start-up activities. The compression system is designed for large flow rates, built to be reliable, efficient and flexible. The versatile technology is of particular value for developmen

First Subsea Completes Work on Goliat FPSO

Subsea connector specialist First Subsea informs it has completed the installation of bend stiffener connections for gas lift and production risers, power cables and umbilicals, for the Goliat FPSO in the Norwegian Barents Sea. Operated by ENI Norge AS, the Goliat FPSO is the first offshore oil development in Norway's Arctic region, in the Barents Sea. In total the Goliat FPSO features 11 Type II bend stiffener connections (BSC) at present, with a further 10 receptacle I-tubes preinstalled within the base of the vessel, enabling more tie-backs to be added as field production increases.

December 2025

December 2025