New Offshore Wind Foundation Tested

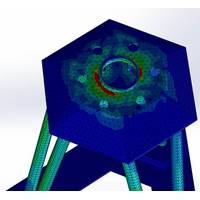

around the base of the structure if left unprotected.Dr. David Todd, Business Development Manager for Research at HR Wallingford, said, “We are looking forward to working with OWLC on this exciting new foundation concept. The foundation will be subjected to rigorous physical testing in the Fast Flow Facility, a unique wave-current-sediment flume designed for the offshore wind market, making it the ideal location for installation, survival and scour testing of offshore wind foundations.&rdquo

Researchers Set Out to Future-proof Offshore Wind Turbine Monopiles

.'The effort, part of PROTEUS, an EU-funded Hydralab+ project, will see leading scour researchers from Ghent University, Leibniz University Hannover and the University of Porto, alongside IMDC nv and the Department of Mobility and Public Works (Belgium), collaborate at HR Wallingford’s Fast Flow Facility (FFF).PROTEUS, which stands for the ‘PRotection of Offshore wind Turbine monopilEs against Scouring’ will facilitate the conducting of a series of large scale experiments over a seven-week period in the FFF flume at HR Wallingford’s U.K. physical modelling facilities.Dr. David

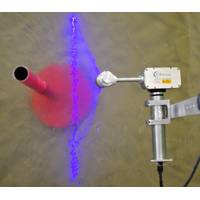

Seatronics Sells 2G Robotics' ULS-200 Laser Scanner

on the impressive level of resolution and accuracy it delivers. Seatronics has an excellent track record of customer service and technical support and provided close client liaison in both commercial and technical matters leading up to the sale.” HR Wallingford recently opened the Fast Flow Facility, one of the world's largest marine test facilities, with a unique, dual-channel flume for wave-current-sediment modeling. The company conducted trials with the ULS-200 at the facility, with technical support from Seatronics and 2G Robotics. HR Wallingford subsequently purchased a ULS-200 and

February 2025

February 2025