MTR100: VideoRay

mission partners throughout the world to develop and prove the small ROV tool for a wide range of applications, and underwater accessory manufacturers now develop sensors around the size and payload capacity of VideoRays, meaning users can choose from a large array of sonars, positioning systems, metal thickness gauges, cathodic protection, water quality and radiation measuring devices, and many other underwater tools and sensors. The ROVs’ plug-and-play technology allows users to quickly attach sensors and accessories in the field. VideoRay’s new Mission Specialist Series features

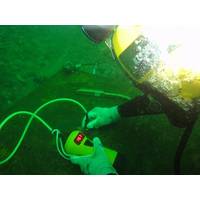

Divers Monitor HMS A7 Using Underwater Thickness Gauge

Underwater thickness gauge enables divers to monitor conditions of sunken submarine A team of divers from the A7 Project have measured the metal thickness of the sunken HMS A7 submarine using a Cygnus DIVE underwater ultrasonic thickness gauge, allowing them to determine the current condition of the submarine and to monitor its deterioration over time. The A7 Project is part of The SHIPS Project (Shipwrecks and History in Plymouth Sound), which is being run by a local group of divers and shipwreck enthusiasts. The project aims to record the long maritime history of Plymouth and the

Tritex Underwater Metal Thickness Gauge

The Mark 2 Tritex Multigauge 3000 Underwater Thickness Gauge, from U.K.-based Tritex NDT Ltd., uses multiple echo to completely ignore coatings up to 20mm thick, only the metal thickness is measured. All measurements are error checked to ensure only accurate readings are displayed, even on uncoated metal. According to the manufacturer, the gauge is simple to use, with little operator input, and has a large bright 10mm display which ensures it can be easily read by the diver, even in poor visibility. The gauge uses multiple echo and single crystal probes in accordance with class

Free Annual Calibration on Tritex Multigauge 3000

UK based, Tritex NDT Ltd are now offering free annual calibration for the life of their entire range of products, including the popular Multigauge 3000 Underwater Metal Thickness Gauge. The gauge is used to measure metal thickness to determine levels of corrosion, without having to first remove coatings. Only the metal substrate is measured due to the Multiple Echo technology used. The Multigauge 3000 is a simple, robust underwater thickness gauge designed to survive extremely harsh conditions that exist in the offshore and underwater industries worldwide. The large bright red 10mm LED

Cygnus Underwater Gauge Launched in the Middle East

East region. Founded in 1983, Cygnus pioneered the digital multiple echo technique. The technique has long since been the industry standard for accurate measurement of material thickness. Driven by the need for a handheld device, multiple echo digital thickness gauges were developed to measure metal thickness through protective coatings in a reliable and repeatable way. The new DIVE MK2 underwater gauge comes handy with a number of key features. It has a bright AMOLED display, updated topside and reporting software and the introduction of twin crystal probes to assist in taking measurements on

Tritex NDT Opens U.S. Office

Tritex NDT Ltd. said it has opened an office in the United States as part of an ongoing strategy of expansion. Tritex manufactures multiple echo ultrasonic thickness gauges that measure metal thickness whilst ignoring coating. The company reported steady growth and an increasing global demand for their product range, leading the opening of the new office in Newark, New Jersey, which Tritex said will better serve their customers in North and Central America, including Canada. Tritex NDT have taken this initiative to offer their multiple echo ultrasonic thickness gauges into these regions while

Subsea Testing & Training Center in Demand

company has chosen a leading subsea testing and training facility in Scotland to test and photograph its latest product, which was launched earlier this week. Cygnus Instruments decided to use subsea trials and training centre, The Underwater Centre, based in Fort William, to test their new metal thickness meter because of its unique replication of offshore facilities that are not available elsewhere. Representatives from Dorset-based Cygnus spent time at the Centre where a photographer dived with one of the classes and used students to test the equipment and act as models for promotional

February 2025

February 2025