Major Gas Supplier Norway Closely Monitoring Baltic Sea Pipe Burst Probe

measures," a spokesperson for Gassco, which operates Norway's gas pipeline network, told Reuters.There have been no reported incidents in Norway, the spokesperson added.On Wednesday, Norwegian police said it had increased patrols around onshore installations on the west coast, which include the Mongstad oil terminal and two gas processing plants, Kollsnes and Kaarstoe.EXPLAINER-What is the Balticconnector pipeline?"The security level has been raised since the events of last year, and still is," said a spokesperson for oil lobby group Offshore Norge, referring to the sabotage of the Nord

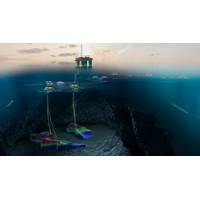

Subsea 7 Wins Johan Sverdrup 2 Contract

, Aker BP (11.5733%) and Total (8.44%).The first phase of the development, including the development of four platforms (accommodation and utility platform, processing platform, drilling platform, riser platform), three subsea installations for water injection, power from shore, export pipeline for oil (Mongstad) and gas (Kårstø), is nearly 90% completed, with expected production start in November 2019.In phase 1, Subsea 7 was responsible for delivery and installation of several subsea components and tie-in of pipelines at the field.Phase 2 of the Johan Sverdrup development was approved by

TechnipFMC Scores EPCI Work from Neptune

in 1989, and a plan for development and operation (PDO) was delivered and approved by the Norwegian authorities in 2007. The field is developed with five subsea templates tied to the Gjøa semisubmersible for processing and export. Production started in 2010. Oil is exported by pipeline to Mongstad and gas by pipeline to St. Fergus in the UK. The Gjøa P1 segment is located in the northern part of the Gjøa field. Neptune operates the license with a 30% stake, and its partners are Petoro (30%), Wintershall (20%) OKEA (12%) and DEA (8%)

Norway’s Largest Oil Pipeline Now in Place

and longest pipeline reached the Johan Sverdrup field in the North Sea.The last pipe of what is now Norway’s longest and largest oil pipeline was installed by the vessel Saipem Castorone, right next to the riser platform at the Johan Sverdrup field. The 36-inch pipeline extends 283 km from the Mongstad oil terminal outside Bergen to the giant field in the North Sea.“We have together with our supplier Saipem succeeded in laying the oil pipeline to Johan Sverdrup without any serious incidents. It has been a significant operation, involving more than 600 people at the most, who have welded

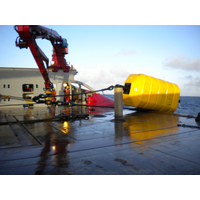

DSM Begins Work for New Mooring Contract

products and services to the Deepsea Bergen semisubmersible drilling rig on the Norwegian Continental Shelf. Austrian oil & gas company OMV has deployed the semi-submersible rig to support drilling activities in the region. With operations coordinated out of DSM’s equipment base in Mongstad, Norway the pre-lay mooring Equipment and services provided will include chain, fiber ropes, anchors, connectors, buoyancy and handling equipment as well as mobilization and demobilization services. The contract with OMV also follows DSM’s successful provision of mooring services to the Island

Statoil: Fram C East Starts Production to the Troll C Platform

to boosting Troll C production and activities. Fram C East is a long production well drilled from the existing Fram subsea template. Production will be tied back to Troll C, an important North Sea hub. Gas will be transported to Kollsnes via Troll A, whereas oil will be piped to Mongstad for further processing. Originally estimated at some NOK 800 million ($97.5 mln) capital expenditures have now been reduced to some NOK 600 million ($73.3 mln) thanks to a simple, smart well concept and significantly increased drilling efficiency. “Fram C East is a small

Statoil, Partners Submit PDO for Byrding

, Statoil’s senior vice president for project development. The Byrding development includes a duo-lateral well drilled from the existing Fram H-Nord subsea template through which oil and gas from Byrding will flow to Troll C. Oil and gas will be piped from there through existing pipelines to Mongstad and Kollsnes respectively. Capital expenditures have been reduced from initially approximately NOK 3.5 billion to the current estimate of approximately NOK 1 billion. “Byrding shows that successful improvement efforts in Statoil, and in this case particularly within drilling and well

Construction Begins on Johan Sverdrup Riser platform

play a key role on the field centre, as it will be the receiver of land-based power that will maintain operation on the Johan Sverdrup field for more than 50 years. From this platform the oil and gas from the huge Johan Sverdrup reservoir will be exported to land, to Kårstø (gas) and to Mongstad (oil). The riser platform also represents the future of the Johan Sverdrup field. “Our Johan Sverdrup development is based on 40 years of experience from the Norwegian continental shelf. We know that by working hard every day we are able to improve the oil and gas recovery and extend

AVEVA 3D Plant Design Solution for Statoil

and long-term operations.” Statoil is currently using AVEVA software on 52 Brownfield and 7 Greenfield models plus the new Johan Sverdrup field development project that today consists of seven models. Older plants such as Snøhvit LNG Plant in the Barents Sea, the refinery at Mongstad in Norway and Kalundborg in Denmark, and the gas treatment facility at Kårstø have been converted to AVEVA PDMS. Statoil’s new strategy to standardize on AVEVA E3D offers the potential for significant project efficiencies in the design, operation and revamp of all Statoil facilities

August 2025

August 2025