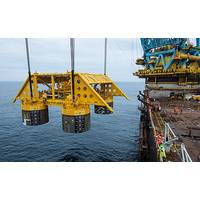

TechnipFMC Bags $1B Contract with Petrobras

TechnipFMC has been awarded 'major' integrated engineering, procurement, construction, and installation (iEPCI) contract by Petrobras to deliver the Mero 3 HISEP project, which uses subsea processing to capture carbon dioxide-rich dense gases and then inject them into the reservoir.The contract covers the design, engineering, manufacture, and installation of subsea equipment, including manifolds, flexible and rigid pipes, umbilicals, power distribution, as well as life of field services.For TechnipFMC, a 'major' contract is over $1 billion. This award will be included in first quarter

Can the Subsea Factory Support a Net Zero World?

, you can see the energy savings that we can realize. This makes, in my opinion, the subsea factory concept all the more relevant and compelling. So, have we always known that the subsea factory helps produce lower-carbon energy?Over the past 20 years, there has been an enormous amount of subsea processing technology development and, for some time, we have known that this technology has energy efficiency and low-emission benefits. But, if we’re honest, these were not among the top priorities until very recently.In today’s net zero context, we are seeing those added benefits under a different

DNV GL RP for Subsea Pumping Systems

, Shell and Woodside in addition to four major systems suppliers; Aker Solutions, Baker Hughes, OneSubsea, and TechnipFMC. The project sought to address several obstacles to subsea processing and pumping. These include overcoming the sector’s perceived novelty and unfamiliarity of subsea processing technology which can prevent new projects from being sanctioned, even though the concept is proven. Dozens of subsea pumps have been installed and several have been in operation for more than a decade, for example off the coast of Norway and offshore Angola.Lower emissions and the decarbonization

Pumping up Subsea Processing via Standardization

. “With today's low oil price, it is more important than ever to create cheaper, leaner and standardized subsea solutions. This challenge goes across the oil industry and collaboration is key. The industry needs to lower costs to enable more subsea developments and increase the use of subsea processing technology,” says Margareth Øvrum, Executive Vice President of Technology, Projects & Drilling at Statoil. “The oil and gas industry needs to re-assess stand-alone host developments due to higher costs and look more closely at tie-back opportunities. Subsea processing technologie

Aker, Fjords Join Forces

Solutions. "This brings us one step further in developing fully-fledged subsea production and processing systems that increase oil and gas recovery and lower costs for our customers." Aker Solutions is a leading provider of subsea production systems with a strong base of subsea processing technology and competence from projects including the Åsgard subsea compression development. Fjords Processing, previously known as Aker Process Systems, has in recent years strengthened its position by acquiring the separation specialist companies Opus Maxim Ltd and Separation Specialists

Statoil, DNV GL Drive Subsea Factory Interface Standardization

establish an industrial cooperation to introduce an international industry standard for subsea process technology. DNV GL will lead a joint industry project (JIP) with important subsea operators to find industrial standards which will make it more profitable to develop larger projects with subsea processing technology. Today, subsea developments are characterized by tailor-made solutions. Subsea pumps have been used in many oil fields, and the first subsea compression systems will be installed in 2014 to increase gas production from the Åsgard and Gullfaks fields. By standardizing tie-in

Subsea Hardware Spending to Double to $124 Billion

advanced subsea hardware solutions are resulting in fields being increasingly developed in deeper waters, in remote locations and in more extreme metocean conditions. In addition, the offshore industry is being challenged to recover smaller, more widely scattered reserves. The growing use of subsea processing technology, such as subsea separation, multi-phase pumping and gas compression, as an alternative to the use of fixed processing platforms will also tend to provide upside potential. Moves in the industry, particularly from operator BP, to develop 20,000 PSI technology could unlock fields that are

February 2025

February 2025