DeepOcean Bolsters Subsea Robotics Fleet with Eight New ROVs

units available as options. The program marks a significant step forward in the adoption of modern electric ROV technology and will support more sustainable subsea operations going forward.“Our operating model is founded on engineering, project management, proprietary technology, an extensive subsea tool pool, ROVs and a versatile subsea fleet.“The ROVs serve as our eyes and hands on the seabed, playing a vital role in this equation. We have collaborated closely with Kystdesign for 26 years, and we are excited to take the development to the next level, together,” says Øyvind

DeepOcean Expands Subsea Market Scope with Shelf Subsea Acquisition

and will form the company’s business region, DeepOcean APAC. The parties have agreed not to disclose the financial details of the transaction.The acquisition enables global expansion of DeepOcean’s operating model founded on engineering, project management, proprietary technology, subsea tool pool, ROV’s and access to a versatile subsea fleet.The subsea markets in APAC and the Middle East are characterized by attractive fundamentals with growing demand for subsea IMR (Inspection, maintenance and repair) and recycling services, and a growing offshore wind market.Similar to DeepOcean

Norway: Funding Granted for Deep-sea Mineral Core Sampling Tech

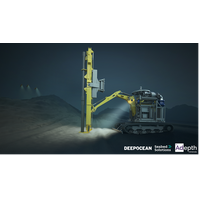

components are replaced, and the equipment is "marinized" and adapted to operations in the deep sea.Norway Eyes Sea Change in Deep Dive for Metals Instead of OilThe FlexiCore will be mounted to the “Seabed Excavator”, an existing electric, crawling, flexible and powerful subsea tool carrier designed for deep-sea operations down to 4,000 meters and has previously completed projects at 3,200 meters. The Seabed Excavator and FlexiCore drilling equipment are electrically powered and remotely controlled from an offshore service vessel.Adepth Minerals expect that the FlexiCore

Siem LCV on Bareboat Charter to Swire Seabed

basis. Swire Seabed also owns several mobile assets including two 3,000-meter rated mobile Kystdesign Supporter work class ROV systems, a 6,000-metre depth rated Argus Bathysaurus XL WROV, a Sperre Sub-fighter 15k Observation ROV and Seabed Excavator, a cutting-edge multipurpose subsea tool carrier and dredging vehicle.

Swire Seabed Buys Fourth Subsea Vessel

basis. Swire Seabed also owns several highly sophisticated mobile assets including two 3,000-metre rated Kystdesign Supporter WROV systems, a 6,000-metre depth rated Argus Bathysaurus XL WROV, a Sperre Sub-fighter 15k Observation ROV and Seabed Excavator, a cutting-edge multi-purpose subsea tool carrier and dredging vehicle.

Flangeless Subsea Plug Launcher for Pipeline Upgrade

. It was during this time that Statoil asked Balltec to investigate the possibility of designing and manufacturing a subsea plug launcher to their unique specifications. The plug launcher was built on technology used in Balltec’s recently developed flangeless subsea PIG launcher, a subsea tool used to deploy a PIG into a pipeline without the need for a bolted flange connection or diver intervention. The existing technology was significantly re-designed to accommodate a larger smart plug of 4.5 m in length with a mass of 1,500 kg. The plug launcher gripping mechanism was built to withstand

2 Mobile WROVs with LARS for Swire Seabed

range of subsea operations and its team of highly experienced onshore and offshore specialists. Swire Seabed’s other mobile subsea assets include a 6,000 metres depth rated Argus Bathysaurus XL WROV, a Sperre Subfighter 15k observation ROV and the Seabed Excavator, a cutting-edge multi-purpose subsea tool carrier and dredging vehicle. This is in addition to the six WROVs permanently installed on Swire Seabed’s dedicated subsea vessels. Both the WROVs and LARS are designed for harsh and challenging environments and can be easily transported and mobilised on board Offshore Support

J2 Subsea Opens Subsea Tooling Facility in Houston

J2 Subsea, an Acteon company, informs it has opened a new subsea tooling facility at sister Acteon company, Seatronics’, subsea electronics location in Houston. The new facility marks the next stage in J2 Subsea’s global expansion plan, the company said. North American customers can now access a suite of subsea equipment for diver and remotely operated vehicle (ROV) applications. The new facility includes a workshop for tool preparation, servicing and support. It will provide torque tools, analyzers, cutters, manipulators, intensifier panels, grinders, dirty work packs, jetters

GROW Funding Nurtures New Subsea Tech

Offshore Marine Management (OMM) has secured GROW:OffshoreWind funding to build a new subsea tool which aims to reduce project costs and improve health and safety offshore. The new tool has been designed using OMM’s experiences of working offshore and its technology will bring time savings during offshore operations, consequently driving down associated vessel, equipment, vessel and personnel costs. The subsea tool, which is currently being constructed by Darlington-based Subsea Innovation, will see improvements during the installation phase by removing the need for deep

December 2025

December 2025