Fairbanks Morse Defense, Caley Ocean Team on LARS

Fairbanks Morse Defense (FMD) finalized a teaming agreement with Caley Ocean Systems, a Pryme Group Company, to pursue launch and recovery, and other naval mechanical handling opportunities. This collaboration expands FMD's capabilities to provide best-in-class marine technologies while strengthening Caley Ocean Systems’ presence in the U.S.Established in 1968 and based in Glasgow, Scotland, Caley Ocean Systems has established itself as a manufacturer of offshore handlingsystems catering to international markets. The company specializes in engineering design, assembly, testing, installati

Pryme Group Launches Specialist Tooling Systems for Offshore Wind Installation

Engineering firm Pryme Group said Wednesday it had launched two specialist tooling systems - Pile Fixation Tool (PFT) and PileProp - for offshore wind installations, via Caley Ocean Systems. The company said the tools were designed to support the installation of monopile and jacket foundations for offshore wind, by providing a localized, rigid deflection constraint - and in the case of the PileProp system - independent of vessel interaction or station - before the critical grouting process of securing the foundations.Pyme Group described the Pile Fixation Tool as a monopile foundation installation

New Linear Cable Engine for Rapid Telecoms Cable Lay

Caley Ocean Systems, part of the Seanamic Group, has developed a high speed linear cable engine (LCE) for telecoms cable laying. Operating at speeds up to 10 knots, the fully containerized Caley LCE provides complete control of deployment of telecoms cable and repeaters. Caley offers a range of linear cable engines optimized for laying and recovering a wide variety of cable types. The engine is assembled within a customized and fully CSC certified 20ft ISO container, with curtain access to the sides and doors at either end to allow easy cable throughput. The LCE includes a built-in

MTR100: Caley Ocean Systems

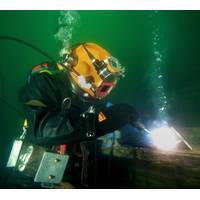

, with development of 18-man and 24-man DNV classed, twin bell, saturation dive systems; and a 3m wide portable saturation dive bell handling system - one of the most ultra-compact, fully road transportable, bell handling systems ever made. Based in Scotland and established in 1968, Caley Ocean Systems – a business within the Seanamic Group – produces offshore handling systems for the oil and gas industry; oceanographic, marine science and naval emergency vessels; and offshore power and telecom cabling. The company’s services include marine and offshore handling systems

Caley Supplies Dive Bell Handling Systems for DSCVs

Offshore handling systems specialist Caley Ocean Systems is supplying Singapore-based diving and subsea equipment company Flash Tekk Engineering with saturation dive bell handling systems for its client Ultra Deep Solutions’ vessels Deep Installer and Van Gogh DSCVs. The Caley dive bell handling systems are designed for deployment and recovery of a 24-man DNV classed twin bell saturation dive system for the Ultra Deep Installer, and a DNV classed 18-man bell saturation dive system for the Van Gogh, for operations to 300 meters water depth. On each dive support vessel, the bell is

JFD Orders Caley's Dive Bell Handling System

Caley Ocean Systems, part of the Seanamic Group, is supplying a portable saturation dive bell handling system to submarine rescue and specialist subsea operations company, JFD (a part of James Fisher & Sons). Caley has designed the dive bell handling system to meet exacting width requirements, at just 3m it will be one of the most ultra-compact, fully road transportable, dive bell handling systems ever made. The dive bell handling system is designed for over-the-side and moon pool deployment of the bell. Its modular construction, together with small footprint, enable the bell handling system to

Seanamic Expands Global Umbilical Business

umbilicals business with a new Umbilical International facility in Glasgow. Initially it will offer umbilical repair and refurbishment for operators and contractors, in the lead up to full umbilical and cable manufacture. Comprising Houston-based, Umbilicals International (UI) and Glasgow-based Caley Ocean Systems, Seanamic supplies fully integrated umbilical and handling systems for well intervention, workover and BOP (MUX and direct Hydraulic), saturation diving and subsea habitats, ROVs and submersibles. Umbilicals International designs and manufactures custom dynamic thermoplastic umbilicals

MTR100: Caley Ocean Systems Ltd.

than a conventional IWOCS. The Caley bespoke, high redundancy cable tensioner system, developed for Prysmian Group, accommodates both cable and outsized bodies, allowing uninterrupted tensioning of the cable during installation. The Company Based in Glasgow, Scotland, and established in 1968, Caley Ocean Systems Ltd. has a strong international reputation as a center of excellence in offshore handling systems for the oil and gas industry; oceanographic, marine science and naval emergency vessels, and offshore cabling. Caley Ocean Systems is a business within the Seanamic Group, which also includes

MTR100: Caley Ocean Systems

such as WHOI’s new Alvin submersible LARS based on an upgraded Caley A-frame first built more than 30 years ago; A-frame and winches for Geological Survey of India’s new research vessel; and deepwater handling systems for loads in excess of 950t at depths of 1,300m. The Company Caley Ocean Systems has a strong international reputation with an experienced engineering team and dedicated manufacturing facilities. Caley Ocean Systems’ services includes marine and offshore handling systems development, design consultancy, professional project management and engineering services. In

December 2025

December 2025