JDR Secures Cabling Work at Coastal Virginia Offshore Wind Project

GW, is set to become the largest offshore wind farm in the United States, capable of powering approximately 660,000 homes.To remind, Dominion Energy has already installed 78 monopile and four offshore substation foundations for as part of the first offshore construction campaign for the 2.6 GW project.DEME Group's heavy lift vessel Orion has been tasked with the installation of the monopile foundations, with the first offshore installation campaign concluded in November 2024.First Installation Campaign at Coastal Virginia Offshore Wind Farm Wraps Up"The CVOW project represents a major step forward

Prysmian Bags €1.8B Order to Connect Dutch Offshore Wind Farms

fibre optic cable. Submarine cables will be manufactured at Prysmian Group’s plants in Pikkala (Finland) and Arco Felice (Italy), while land cables will be produced in Gron (France). Marine installation operations will be performed by Prysmian`s cable laying vessels and in partnership with Deme Group, a Belgian offshore installation contractor.Deployment of innovative 525 kV HVDC technology for submarine cable systems525 kV HVDC XPLE Cable System - ©TenneT"Prysmian Group has reached in 2022 a significant milestone, successfully passing the development and testing of the first 525

Transocean's Drillship to be Used for Deep-Sea Mineral Exploration

Offshore drilling company Transocean has agreed to invest in DEME Group’s subsidiary Global Sea Mineral Resources NV (“GSR”) in exchange for a non-controlling stake in the company. GSR is the deep-sea mineral exploratory company engaged in the development and exploration of deep-sea polymetallic nodules that contain metals critical to the growing renewable energy market, and is a developer of nodule collection technology.Transocean has agreed to contribute the stacked Ocean Rig Olympia drillship for GSR’s ongoing exploration work, as well as make a nominal cash investment.

Subsea Mining: All Eyes on Marine Minerals Offshore Norway

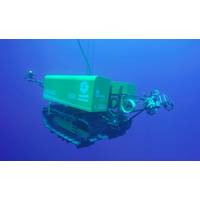

were adopted in 2000. However, the same for exploitation, under expected 30-year licenses, isn’t expected until 2022, at the earliest.Still, companies are gearing up for this activity, creating technologies to support mineral mining. In what’s been billed as a world first, Belgium-based DEME Group’s Patania 2 nodule collector has been undergoing trials in 4,500 m water depth in the Clarion Clipperton Zone of the Pacific Ocean (where it had a minor disconnection mishap in April). Soil Machine Dynamics in Newcastle, UK, recently unveiled a new nodule collection solution, the QC2000 Nodule

Mining Robot Stranded on Pacific Ocean Floor in Deep-sea Mining Trial

A seabed mining robot being tested on the Pacific Ocean floor at a depth of more than 4 km (13,000 ft) has become detached, the Belgian company running the experimental trial said on Wednesday.Global Sea Mineral Resources (GSR), the deep-sea exploratory division of dredging company DEME Group, has been trialling Patania II, a 25-tonne mining robot prototype, in its concession in the Clarion Clipperton Zone since April 20.The machine is meant to collect the potato-sized nodules rich in cobalt and other battery metals that pepper the seabed in this area, and was connected to GSR’s ship with a 5km

Deme Offshore Joins Neptune's Hydrogen Project

Offshore installation contractor Deme Offshore has joined Neptune Energy's PosHYdon pilot, the world’s first offshore green hydrogen project, being developed in the Dutch North Sea.Part of the Belgian Deme Group, the company joins as a partner and will provide the hydrogen unit for installation on the Neptune-operated Q13a platform. The pilot aims to integrate three energy systems in the North Sea: offshore wind, offshore gas, and offshore hydrogen by producing hydrogen from seawater on the Q13a.Lex de Groot, Managing Director of Neptune Energy in the Netherlands, said: “The

"Bonny River" TSH Dredger Delivered

capable of dredging hard soil and able to work in water depths of more than 100 m.“The design of the Bonny River is inspired by a drive to continuously innovate from an ecological and efficiency perspective," said Jan Gabriel, Head of the Technical Construction and Conversion Department at DEME Group. Bonny River is driven by a pair of Schottel Controllable Pitch Propellers type SCP 129 4-XG with an input power of 8,000 kW each and a propeller diameter of 4.5 m. It reaches a speed of approximately 16 knots. Beyond this, maximum maneuverability and propulsion efficiency are provided by

Video: Soil Testing Vehicle Dives Deep

DEME Group's GSR (Global Sea Mineral Resources) exploration activities in the Clarion Clipperton Zone (CCZ) during the company's 2017 Pacific campaign narrowed in on three major elements: resource assessment, technology and environment.To verify resource estimates undertaken during GSR's 2014 and 2015 campaigns, nodules were collected using deep-sea dredges and box cores.The technological aspects involved the deployment of Patania I, the first tracked soil testing device vehicle to reach and travel the seafloor at depths of more than 4,500 m. The vehicle is the first of a series of three

Royal IHC launches DEME’s LNG-powered TSHD

analyses and improves the bow thruster performance. “With this new generation of dual fuel hoppers, DEME is setting new standards in environmental performance for the dredging industry, and we are proud to be at the forefront of these developments,” says Alain Bernard, Director and CEO DEME Group. “Both the SCHELDT RIVER and MINERVA will comply with the strictest international and local environmental regulations.”

February 2025

February 2025