NOAA and Sofar Advance Weather Forecasting

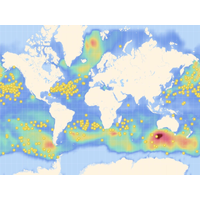

NOAA’s Geophysical Fluid Dynamics Laboratory (GFDL) and Sofar Ocean have partnered to build modeling systems that advance marine weather forecasting.GFDL and Sofar’s three-year cooperation, which began in late 2024, combines parallel efforts at each organization to produce a coupled atmosphere-wave-ocean model that improves the accuracy of global marine weather forecasts and regional extreme weather scenarios.Scientists at NOAA and Sofar are already leveraging preliminary versions of the coupled model to produce more accurate ocean weather forecasts and improve safety at sea for coastal

DEEP Partners with Unique Group to Deliver Subsea Human Habitat

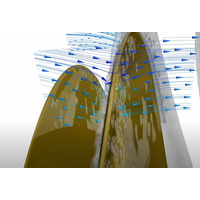

, and will be followed by the Sentinel habitat in the years following, marking a significant advancement in ocean exploration.Unique Group’s scope includes foundation design and geotechnical survey management, metocean data collection, and cyclonic survivability studies. Using Computational Fluid Dynamics (CFD), they optimized the foundation’s stability against extreme ocean forces. The foundation base plate, currently under fabrication in the USA, weighs over 300 tons and incorporates multiple anchoring systems.The company also engineered the mooring spread for the habitat support buoy

Microscopic Wave Machine Mimics Ocean Waves

and optical fields in this system are manufactured using the same techniques as those used for semiconductor chips, we can engineer the fluid’s effective gravity, dispersion, and nonlinearity with extraordinary precision.“Future experiments could use the technology to discover new laws of fluid dynamics and accelerate the design of technologies ranging from turbines to ship hulls.“Experiments on this tiny platform will improve our ability to predict the weather, explore energy cascades and even quantum vortex dynamics – questions central to both classical and quantum fluid mechanics

NOAA Predicts Cooler Deep Waters for Gulf of Maine

and Fisheries Initiative (CEFI) by scientists across NOAA Research and Fisheries, with input from the National Ocean Service, National Environmental Satellite and Data Information Service and the National Weather Service.The outlook is based on two models developed by NOAA’s Geophysical Fluid Dynamics Laboratory. The first is SPEAR, the “Seamless System for Prediction and Earth System Research”, which provides large-scale predictions for the ocean, atmosphere and land. The SPEAR output is then fed into a higher-resolution regional model, built with the Modular Ocean Model version

Watch: Soft Robot Swims Like Manta Ray

, silicone body that contains a chamber that can be pumped full of air. Inflating the air chamber forces the fins to bend – similar to the down stroke when a manta flaps its fins. When the air is let out of the chamber, the fins spontaneously snap back into their initial position.Studying the fluid dynamics of manta rays also played a key role in controlling the vertical movement of the soft robot. “We observed the swimming motion of manta rays and were able to mimic that behavior in order to control whether the robot swims toward the surface, swims downward, or maintains its position in the

EDGE and Fincantieri Join Forces to Develop Advanced Subsea Defense Systems

benefit of the UAE and other navies worldwide.“This agreement between Fincantieri and EDGE underscores a commitment to pioneering advancements in underwater technologies, combining engineering excellence with a forward-thinking approach. The underwater domain presents unique challenges, from fluid dynamics to communication and autonomy, which demand innovative and resilient solutions.“Together, we aim to develop systems that meet the highest standards of interoperability, addressing critical needs within both the defense and energy sectors. Our efforts are dedicated to setting new benchmarks

All American Marine Delivers Research Vessel for the University of Hawai’i at Mānoa

included transom mounted Humphree interceptors. The lift produced by the hydrofoil reduces the hull resistance while increasing speed and load-bearing capability, while the interceptors offer additional trim control.This advanced hull shape was custom designed using digital modeling and computational fluid dynamics (CFD) analysis testing. The vessel’s design offers all passengers and crew a smooth ride and comfort, as the hull provides a cushioned effect when encountering waves. For the operator, one valuable feature of this vessel is the excellent fuel economy, while also maintaining an estimated

AAM Delivers Survey Vessel for NV5-Geodynamics

hull components are designed to break up wave action and ensure reduced drag while enhancing passenger comfort. According to AAM, the design is proven to have both low-wake wash energy and increased fuel economy. This advanced hull shape was custom designed using digital modeling and Computational Fluid Dynamics (CFD) analysis testing. The vessel’s design offers all passengers and crew a smooth ride and comfort, as the hull provides a cushioned effect when encountering waves. For the operator, the most valuable feature of these vessels is the excellent fuel economy, which consumes approximately

New System Reduces Underwater Radiated Noise from Ship Propellers

in the low-frequency range, is disorientating marine fauna and disrupting their communication signals, leading to behavioral changes or extinction. We now have a cost-effective, easy-to-apply solution that prevents this from happening.”Following four years of comprehensive computational fluid dynamics (CFD), modeling and cavitation tunnel tests during the solution’s development phase at Strathclyde, it was demonstrated that PressurePores can reduce cavitation volume by almost 14% and URN by up to 10dB, Oscar Propulsion said.According to the company, results were further verified in tests

December 2025

December 2025