MacArtney Introduces 9-Contact SubConn Connector

enhanced security. The ninth contact in this connector is intended for a screen, providing an extra layer of data protection and ensuring reliable performance.The SubConn Micro Circular connector series provides dependable performance even at great ocean depths. High-quality materials such as chloroprene rubber for the connector body and options including brass, stainless steel, titanium, anodized aluminum or PEEK for the bulkhead body resist corrosion and pressure to ensure long-term durability and reliability.Each of the nine contacts is rated at 5 A, with a maximum of 20 A per connector, meeting the

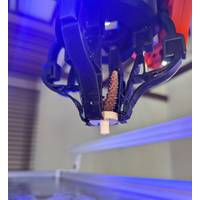

Robotic Hand Designed to Move Coral

handle delicate coral. Sarah Baldwin, a Mechatronics Engineer who conducted this research while at CSIRO, said the gripper design was innovative due to traditional robotics' unsuitability in corrosive saltwater.“To overcome corrosion, we 3D printed the gripper from hard polymer and soft rubber, with only a few screws and bolts,” Baldwin said. Stephen Rodan, inventor of CHARM and President of Beyond Coral Foundation, said: “This is the first time in history that a robot apparatus ever picked up a coral and transferred it safely between tanks using a soft robotic gripper

Not All Underwater Reefs are Made of Coral

the proposed objects or materials are appropriate to deploy in the ocean.For example, decommissioned ships are thoroughly cleaned and drained of fuel and other polluting substances prior to sinking to minimize environmental risks. Some materials that were once used to create artificial reefs, such as rubber, fiberglass, wood and plastic, are now prohibited because they may move from their placed location, damaging nearby habitat, or deteriorate quickly in salt water.Reefed objects can be sunk only in predesignated areas of the U.S. seafloor. These zones, which are usually sandy sea bottom, total about

MTR100: Underwater Cameras, Lights and Ocean Landers

, like wiper brushes and UV LEDs, have been demonstrated.LightsLEDs are ubiquitous. Light goes out the front, while heat goes out the back, making the housing design straightforward. Various approaches to covering the LED in clear materials have been devised, from acrylic flat plates to clear silicone rubber sheets. Some cast the LEDs in a block of clear acrylic. Heat is the principal enemy of LEDs. Much has been written about topside luminaire design, including the use of heat transfer material behind the PCB to carry the heat away from the LEDs (google “CREE LED Luminaire Design Guide”)

Cleanup Day Comes to Philippine Capital's Polluted Bay

Hundreds of volunteers joined a mass cleanup drive along the coast of the polluted Manila Bay in the Philippine capital to mark International Coastal Cleanup Day on Saturday.Volunteers and government workers, including hundreds of coast guard personnel, collected sachets, rubber slippers and other non-biodegradable waste that have been washed in the Manila Bay, a 60 km (37 mile) semi-enclosed estuary facing the South China Sea."This initiative will help make our coastal area in Manila Bay better so that our tourists and visitors will see the beauty of the bay," college student Kendrick Lopez

Bombora Making Progress with 'World’s Most Powerful' Wave Energy Converter

the quayside in Pembroke Dock before loadout to the operational site at East Pickard Bay, where the mWave technology will be validated in the open ocean, advancing it to TRL (Technology Readiness Level) 7/8.”Bombora’s mWave solution involves a series of air-inflated concave cells covered with rubber membranes and mounted into a steel foundation structure secured beneath the ocean’s surface. As waves pass overhead, air is squeezed out of each cell module in sequence, passing through one-way valves and into a duct system fitted with an axial turbine before being recirculated to refill

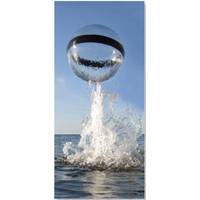

Lander Lab #3: Buoyancy

can be internal or external, providing some design choices. Work is still being done on creating a metal flange to protect the finely polished glass sealing surfaces and provide an o-ring seal. Random surface spalling may be due to residual stresses of the casting and forming operation. Rubber bumpers over the polished glass edge is crutial when the sphere is open to prevent inadvertent damage from impact to the glass.Syntactic Foam: Engineered Syntactic Systems (Attleboro, MA), Trelleborg/Eccofloat (Boston, MA), DeepWater Buoyancy, (Biddeford, ME) < >, SynFoam (Livingston,

Meet NOUS: An Underwater ‘Artificial Mind’

of the crystal has been provisioned in the camera housing that removes marine deposits that develop over time and reduce the effectiveness of the optical system. Thus, a wiper system made for the needs of this particular housing was installed, consisting of a sealed servo motor and a cleaning arm with a rubber cleaning material. The cleaning system is fully and autonomously controlled (via image processing algorithms and optical system quality diagnostics) by the camera computer. During the design phase, the practice of 3D-printer manufacturing was followed for all components to ensure full size functionality

Blue Robotics Expands on the WetLink Line

or penetrators, the WLP is a fraction of the cost while offering validated reliability. The WetLink Penetrator line now has cable gland sizes compatible with cables between 3.7mm to 9.8mm diameter.The patent-pending design of the WLP is based on a compression gland seal design, optimized for sealing rubber jacketed cables at the high pressures seen in the ocean. “The WetLink Penetrator is a game-changing product: with this expanded product line, you can reliably sealjust about any small cable to 950 meter depth for just $12," said Blue Robotics CEO, Rustom Jehangir. "We&rsquo

February 2025

February 2025