SYRENE: An Underwater Embedded Artificial Intelligence Camera for Invasive Fauna Monitoring

for having kindly hosted the camera in their lionfish tank, Helene Leau (Ifremer), SincObs project coordinator as well as Amaury Tisseau, Thomas Morales and Alvaro Scarramberg for their involvement in this project.Credits[1] Green, S.J., et al. (2012)[2] Vaswani et al., 2017 : https://arxiv.org/abs/1706.03762)[3] https://hal.science/hal-04889751About the authorsLaurent Gautier is a mechatronics engineer in IFREMER’s Research and development lab. He is involved in the development of several benthic observatories, as well as in technological devs for scientists.Stephane Barbot is a

ABS Certifies World’s Largest Classed Unmanned Surface Vehicle

American Bureau of Shipping (ABS) has issued classification to the Surveyor, a fully autonomous deepwater unmanned surface vehicle (USV), developed by Saildrone.At 20 meters long and capable of unmanned operations across all of the world’s oceans, the Surveyor is the largest class of USVs from Saildrone, a provider of maritime security, ocean mapping, and meteorological and oceanographic data using unmanned autonomous assets.The USV is capable of long-endurance missions in the open ocean, collecting deep-ocean bathymetry and performing a wide range of maritime domain awareness tasks.The classifica

Hanwha Ocean Floating Turbine Receives ABS Approval

ABS issued approval in principle (AIP) to Hanwha Ocean for its new design of a semisubmersible-type floating offshore wind turbine.The design, named WindHive 15-H3, supports 15-megawatt (MW) turbines on three hexagonal columns. ABS completed design reviews based on class and industry requirements.“Floating offshore wind power is set to play a critical role in the world’s future energy landscape, and we are proud to collaborate with industry leaders like Hanwha Ocean on innovative solutions that are focused on advancing safety at sea,” said Rob Langford, ABS Vice President

Industry Leaders Set to Discuss Future of US Offshore CCS Market

, regulators, and innovators are set to convene for forward-looking conversations on the future of U.S. CCS projects and cutting-edge offshore technologies. Several sessions are planned throughout the day, featuring speakers from TotalEnergies, ExxonMobil, Wood, American Bureau of Shipping (ABS) and others, who will shed more light on CCS research and deliver insights on the current state of CCS industry and future opportunities

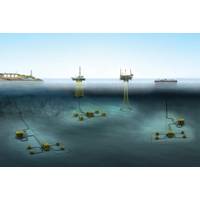

Subsea Digitalization: Remote Control

digitalization will further these goals by providing remote control, optimized operations and enhanced decision-making capabilities.Enabling technology for that digitalization, such as subsea power and communications, continue to evolve, says Miguel Hernandez, Senior Vice President of Global Offshore at ABS, even though the subsea environment poses significant challenges. “Maintaining reliable communication links between subsea assets and onshore or offshore control systems is crucial, but connectivity issues such as bandwidth limitations and signal interference can pose challenges,” says

Deep Trekker Leads $8M AI ROV Ship Modeling and Detection Project

Trekker announced its participation in the AI ROV Ship Modeling and Detection Project, introduced September 12, 2024 at the ALL IN Conference.This initiative, in collaboration with Canada’s Ocean Supercluster (OSC), Qii.AI, The Department of National Defence, Kongsberg Discovery Canada Limited, and ABS Global Canada, harnesses cutting-edge Remotely Operated Vehicle (ROV) technology integrated with advanced artificial intelligence to redefine ship hull inspections for greater precision and efficiency, setting a new standard in the industry.“We are proud to announce the AI ROV Ship Modeling

Inspiring Future Ocean Explorers with Landers

scale, you’re looking for about 2-2.5-lbs negative weight.The release is a dissolvable Life Saver or ice release as we described in Lander Lab 4 (Sept/Oct 2022).Figure 3. The STEM Lander is composed of an 8” plastic trawl float with a center hole, a ¾” Outside Diameter ABS or PVC center shaft, a 2.5-lb bar bell weight with a 1” Dia center hole, and a bicycle flag on a ¼” Dia fiberglass mast. The position of the sphere and counterweight are fixed by using hose clamps above and below the items. Another hose clamp is used to hold the recovery flag

ABS and the US Coast Guard R&D Center Team Up for Maritime Tech Development

American Bureau of Shipping (ABS) and the United States Coast Guard Research and Development Center (USCG-RDC) signed a memorandum of understanding (MoU) as a stepping stone towards collaborative research and development on top-of-mind technologies impacting the maritime industry.Activity under the MoU can include developing joint research publications, new technology qualifications and information sharing in a variety of research areas including remote and autonomous systems for uncrewed surface and underwater vehicles, advanced data analytics involving artificial intelligence and machine learning

ABS and FibreMax Team Up for Floating Wind Mooring Tech

American Bureau of Shipping (ABS) and Dutch company FibreMax have signed an agreement to collaborate on stiffness-driven mooring tendons for the floating offshore wind market.The collaboration, which is principally focused on floating offshore wind assets, will see ABS provide qualification of FibreMax’ s fiber and small rope testing.ABS will evaluate test methods for accuracy in predicting the parameters needed to perform representative analysis, focusing on stiffness, while FibreMax will provide expertise on stiffness, based on its patented Parallel Wound Technology (PWT).“ABS’

December 2025

December 2025