Subsea7 Answers Chevron’s Call for Work at Gas Field off Australia

Subsea7 has secured a contract from Chevron Australia for subsea installation work on the Gorgon Stage 3 (GS3) project, offshore Australia.Subsea7’s scope of work includes project management, engineering, procurement, fabrication, transportation, installation and pre-commissioning of subsea equipment and associated infrastructure at GS3, at 1,350m water depth.Project management and engineering work will start immediately, with offshore operations are expected in 2028.Subsea7 did not reveal the exact value of the contract, but the company deemed it substantial, meaning its value is between $150

TechnipFMC to Supply Subsea Systems for Chevron’s Gas Project off Australia

TechnipFMC has been awarded a significant contract by Chevron to supply Subsea 2.0 production systems for the Gorgon Stage 3 brownfield project in Australia.The contract introduces the first seven-inch series of TechnipFMC’s Subsea 2.0 horizontal subsea trees and includes the delivery of flexible jumpers designed to increase production rates and support flow assurance for gas applications.Gorgon Stage 3 forms part of Chevron’s ongoing development of the Gorgon LNG project, one of Australia’s largest natural gas developments, aimed at sustaining production from the offshore fields

TGS and Chevron Sign Data Acquisition Deal

TGS and Chevron have signed a three-year capacity agreement for marine streamer and OBN acquisition services.The minimum firm commitment under the three-year term of the capacity agreement is 18 months of a combination of OBN and streamer acquisition services. The parties plan to collaborate on seismic acquisition projects utilizing TGS streamer and OBN crews for exploration and development projects.The agreement will deepen the relationship between Chevron and TGS and drive collaboration on technology development in a wide range of geophysical areas from survey design, acquisition technology, data

Carbon Dumping

storage.”2024 was the hottest year on record, and similar climate concerns are being voiced around the world. This week, Alice Harrison, Head of Fossil Fuels Campaigning at Global Witness, directed her LinkedIn post about the DearTomorrow project to the CEOs of Exxon, Shell, BP, TotalEnergies and Chevron. “I’ve just drafted a letter to my daughters. They’re three and five now – I want them to open this letter in 2050, when they’ll be 28 and 30…“Fossil fuels are cooking the planet and super-charging extreme weather and the sorts of droughts that are making

Sulmara Nets $19M Investment for Low-Carbon Offshore Wind Services

to use these advanced systems both alongside and with traditional survey vessels supports improved high-quality data turnaround time while significantly reducing the environmental impact of offshore projects.Sulmara is already delivering services to major customers around the world including Orsted, Chevron and Seaway7 using remote and innovative systems, and BGF’s investment will enable further complex and low carbon data collection in environments that pose a huge challenge to conventional methodologies.As part of BGF’s investment, Richard Pugh and Davis Larssen will join the board as

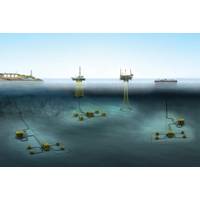

Subsea Digitalization: Remote Control

The more production infrastructure we push to the seabed, the more data we need to pull back up. With it comes opportunity.Chevron’s landmark 6,500 tons of subsea gas compression infrastructure for Jansz-Io demonstrates the scale of what is being put on the seabed, but there’s a diversity of other infrastructure under development that will operate alongside traditional production systems.This includes subsea fluid storage technology from NOV Subsea Production Systems, and TechnipFMC and Sulzer Flow Equipment’s subsea CO2 pumps for new high pressure separation technology

![“Our province has been shaped by the Atlantic Ocean. It can be extremely cold, extremely unforgiving. If it works here, it will work anywhere. The technology we [develop and] use here can be adapted to anywhere else in the world. We are adaptive, we're nimble, we're problem solvers. And at the end of the day, we are collaborative."

Minister Andrew Parsons, Industry, Energy & Technology, Newfoundland & Labrador, Canada. Photo courtesy the office of Minister Andrew Parsons](https://images.marinetechnologynews.com/images/maritime/w200h200padcanvas/province-been-shaped-153427.jpg)

NL Government Helps Power Regional Maritime, Offshore Energy, Subsea Tech Cluster

a great job of promoting the school and what they teach to these kids. Paul's an educator, he's an administrator, he's a data specialist. He's got too many things on his resume to name, but he's absolutely a leader in this province, and a great person to boot.Dr. Lesley James, the Chevron Chair of Petroleum Engineering, is doing a lot of work with us right now on carbon capture and offshore basins, and at the same time recognizing that we have to reduce the emissions offshore. When you look at emission reduction, we are far ahead of most other oil producing nations, but that doesn'

Oceaneering Tests AUV on Pipeline Inspection Pilot for TotalEnergies

, of an estimated 50% compared to existing methods with equivalent quality of the inspection and opportunity to exceed data quality provision through continuous improvement.Freedom, a hybrid AUV/ROV system, is the result of a long-term collaborative relationship between Oceaneering, TotalEnergies, and Chevron dating back to 2014, with Equinor joining the collaboration in 2019.The North Sea pilot for TotalEnergies resulted in an inspection of over 120km of sub-marine pipelines, to add to 60km of near-shore pipelines inspected during an earlier demonstration for TotalEnergies. Freedom demonstrated its

OPT’s Wave-Powered Tech Nears 15MWh of Renewable Energy Production

in the Atlantic, Pacific, Mediterranean, and North Sea.These deployments came from a mix of renewable energy investments from government backed development programs and commercial leases and sales, for customers including Eni, EGP, Office of Naval Research and the DeepStar consortium inclusive of Chevron, CNOOC, Equinor, ExxonMobil, JX Nippon, Occidental, PetroBras, Shell, and Woodside.According to OPT, it has demonstrated and delivered use cases as a proven solution for anti-submarine warfare, intelligence, surveillance, and reconnaissance, unmanned surface vehicle charging (USV), and environmental

December 2025

December 2025