World's First: DNV Launches Floating Solar Power Recommended Practice

DNV, energy industry expertise and assurance provider on Wednesday published what it said was the world’s first recommended practice (RP) for floating solar power projects following a collaborative joint industry project (JIP) involving 24 industry participants."The Recommended Practice (DNVGL-RP-0584) will provide commonly recognized guidance based on a list of technical requirements for accelerating safe, sustainable and sound design, development, operation and decommissioning of floating solar photovoltaic (FPV) projects," DNV said.Floating solar power is a promising renewable

DNV GL Gives Nod for Heerema's Silent Offshore Installation Concepts

can be installed without loud hammering. Hammering can be harmful to marine life and requires noise mitigation systems that produce a considerable CO2 footprint."The concepts being investigated are helical or screw piles and so-called push-in piles," Heerema explained.Heerema said Thursday that DNVGL has now awarded a Statement of Feasibility to both concepts that are under development."Despite the challenges in 2020, this development could continue with the University of Dundee's support, who executed an extensive testing and modeling program," Heerema Marine Contractors said."

Van Oord Installs Slip Joint Foundation at Borssele Wind Farm Site

basis," Van Oord said Tuesday."After years of developing the system in cooperation with its technology partners, Van Oord deployed offshore installation vessel Aeolus to install the Slip Joint foundation this week," Van Oord said.The design and production of the Slip Joint was certified by DNVGL in the autumn of 2019, with MottMcDonald assessing it on bankability aspects. The Borssele Site V project consists of two 9.5 MW wind turbines and Van Oord has been awarded the Balance of Plant scope for this project.Slip Joint foundationThe Slip Joint is based on friction, with the weight ensuring

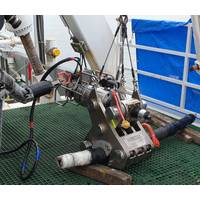

Subsea Cable Gripper Redesigned for Longer Deployments

certification body and classification society, DNV GL, the CRT200 Cable Retrieval Tool is the only cable and umbilical retrieval tool to meet the exacting design codes and standards for marine operations, and offshore and platform lifting appliances. Specifically, the CRT200 satisfies the requirements of DNVGL-ST-N001 Marine Operations & Marine Warranty, June 2016 and DNVGL-ST-0378 Standard for Offshore & Platform Lifting Appliances, May 2016

Subsea Robots in the Splash Zone

by a DNV GL study, the surf is a neglected area of safety: “In areas with harsh environments, such as in the North Sea, it is common to assume that structural details located below or in the splash zone are not accessible for inspection and repair.” The splash zone is defined in DNVGL standard, ST-0126.“Inspection of structures in the splash zone and below water focuses in addition on the corrosion protection systems (steel wall thickness, anodes, coating, etc.), marine growth and scour protection.” Yet, OceanTech’s tools do that hazardous work. The iCon robot

DNV GL Issues Guidance for Subsea Welding

A new recommended practice (RP) to standardize operator requirements for welding and inspection of subsea equipment has been published by DNV GL.DNVGL-RP-B204 “Welding of subsea production system equipment” provides harmonized operator requirements and that will ensure consistency in the fabrication of subsea pressure retaining equipment such as wellheads, Xmas trees, manifolds and jumpers.The RP has been published following a joint industry partnership (JIP), initiated by DNV GL in February 2017. The JIP involving 12 operators, contractors and fabricators addressed supply chain uncertainty

DNV GL RP for Subsea Pumping Systems

A new DNV GL recommended practice (RP) aims to help the oil and gas sector to deliver more cost-efficient and environmentally friendly subsea processing for improved hydrocarbons recovery. DNVGL-RP-F303 Subsea pumping systems provides a comprehensive specification for subsea pumping systems and complements existing industry standards.DNVGL-RP-F303 has been published following a joint industry project including participants from subsea operators Equinor, Petrobras, Shell and Woodside in addition to four major systems suppliers; Aker Solutions, Baker Hughes, OneSubsea, and TechnipFMC. The project sought

Sonsub Hydrone-R Launched in Water

will both dramatically benefit from Hydrone-R and the entire Hydrone Program in the years to come”, said Saipem E&C Offshore Division COO Stefano Porcari.“We are proud to be the forerunner in this technology. Our extensive qualification test campaign has been thoroughly scrutinized by DNVGL and other reputable experts in order to attain a third-party qualification for subsea resident use by November 2019. Having something that can intervene in an autonomous way will reduce vessel costs and the overall carbon footprint for sure, but it will also improve the uptime of a subsea asset thanks

Design Studies for Replacement of R/V DANA

scientific performance- High efficiency in fish stock monitoring- High scientific multidisciplinary performance through versatile design- Year-round operation in North Sea and Baltics- Summer/ Autumn operation in Greenland and Polar waters- Low operational costsThe vessel is designed for class notation DNVGL ✠ 1A, SPS, EO, DYNPOS (AUTS), PC (6), and to comply with the ICES CRR 209 standard for low underwater radiated noise (URN) emission. In carrying out the design, the key design drivers and other design issues have been scrutinized and evaluated to arrive at optimal design solutions, which prioritizes

December 2025

December 2025