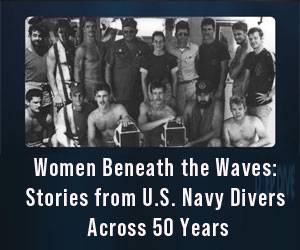

50 Years of Women in Navy Diving: Advancing Opportunity in Tandem with Technology

after 1983.Ensign Sue Trukken fully suited out in the 200-pound Mk V dive helmet and suit during training dives at Basic Diving Officer training, Washington Navy Yard in 1980. Photo courtesy of Sue Trukken.By 1981, the Navy had replaced the Mk V with the newly developed Mk 12 lightweight free-flow fiberglass dive helmet. This unit could be configured for swimmer or full suit modes and supported both air and mixed gas applications, bringing the combined gear weight down to approximately 120 pounds. While lighter, the Mk 12 still presented ergonomic and fit challenges for many women divers, requiring

NOAA and Partners Deploy C-Star USVs to Collect Hurricane Data

also equipped with electric motor thrusters to improve positioning to intercept a hurricane or when winds are weak. Wave condition data, high-resolution images and movies will be available once the C-Stars are recovered. Oshen mission specialists in the UK will remotely pilot the four-foot-long fiberglass USVs, which look like small sailboats, working with NOAA scientists at AOML in Miami and NOAA’s Pacific Marine Environmental Lab (PMEL) in Seattle to position them ahead of hurricanes. They will operate experimentally over the next two months, transmitting near-real-time data which will be

Exail Enhances ROVs with Electromagnetic Sensing Tech

, including turbid waters”, explained Gary Bagot, Sales Director at Elwave. The R7 ROVs equipped with Elwave‘s Tetrapulse sensors will improve the detection, localization, and characterization of both metallic and non- metallic underwater and buried targets, including steel, aluminum, and fiberglass composites.The R7 ROV: A compact and versatile solution for underwater operations combining the agility of a mini-ROV with the capabilities of an observation-class system, the R7’s modular design supports a range of sensors, tools, and payloads. This versatility makes it particularly well-suited

Novielli Boats Unveils Plans for New Production Facility

engaged in the specialized art of boatbuilding.Although increasing production is a critical goal, Novielli remains just as devoted to environmental compliance and safety protocols. Each step in the expansion is reviewed for ecological impact and safe working conditions, whether it involves handling fiberglass materials or managing waste. Plans to introduce eco-conscious resins and recycle construction remnants are high on the company’s priority list. The new facility will follow similarly strict measures, adopting filtered air systems, climate-controlled assembly zones, and advanced exhaust solutions

Inspiring Future Ocean Explorers with Landers

described in Lander Lab 4 (Sept/Oct 2022).Figure 3. The STEM Lander is composed of an 8” plastic trawl float with a center hole, a ¾” Outside Diameter ABS or PVC center shaft, a 2.5-lb bar bell weight with a 1” Dia center hole, and a bicycle flag on a ¼” Dia fiberglass mast. The position of the sphere and counterweight are fixed by using hose clamps above and below the items. Another hose clamp is used to hold the recovery flag. A hole drilled through the bottom of the center shaft provides a place to tie the Life Saver release. A waterproof action camera

Saildrone Launches First Next-gen Surveyor USV

the Surveyor will provide the Navy and other government customers with a cutting-edge solution for open-ocean hydrographic surveys and maritime domain awareness (MDA) missions that require persistent wide area coverage.The Surveyor’s aluminum hull and keel were manufactured by Austal USA, and the fiberglass composite wing and internal components were built at Saildrone’s headquarters in Alameda, Calif.“It is tremendous to see the first vehicle launched of many that will be produced here in Alabama,” said Saildrone founder and CEO Richard Jenkins. “Everyone at Saildrone is very

Not All Underwater Reefs are Made of Coral

objects or materials are appropriate to deploy in the ocean.For example, decommissioned ships are thoroughly cleaned and drained of fuel and other polluting substances prior to sinking to minimize environmental risks. Some materials that were once used to create artificial reefs, such as rubber, fiberglass, wood and plastic, are now prohibited because they may move from their placed location, damaging nearby habitat, or deteriorate quickly in salt water.Reefed objects can be sunk only in predesignated areas of the U.S. seafloor. These zones, which are usually sandy sea bottom, total about 2,200 square

Threat to Whales Complicates US Research into Seaweed for Biofuel

shallow water plot is dedicated to research.Whereas traditional kelp lines are often placed just 2 meters (7 feet) below the surface, "we pin the kelp arrays very close to the ocean floor," he said. "Whales theoretically can go over top of it."He's also experimenting with stiff fiberglass rods to replace rope, designed to break rather than ensnare a whale bumping against them. Lovett hopes their designs, once proven, could be taken to future offshore sites in deeper waters where whales travel.Woods Hole researcher Scott Lindell, the recipient of a $4.9 million DOE grant for sugar

Lander Lab #3: Buoyancy

to solve both the flotation and stability problems.Specific gravity: One of the first techniques to stay within the buoyancy budget is the use of a material selected for its specific gravity, strength and bulk modulus. All things being equal, select the lighter material. For example: Fiberglass (FRP) has a specific gravity of 1.7, whereas aluminum is 2.7. Steel is about 8. Lead is 11.3. Marine grade HDPE is 0.96, which means it floats. We don’t use HDPE for flotation, but it subtracts zero from the buoyancy budget. Most plastics are not prone to corrosion

August 2025

August 2025