Subsea Europe Services, FLANQ Appointed as a Distributor of Voxometer Survey System Across Mainland Europe

with its defense division, FLANQ, has been appointed as a mainland Europe distributor for the Voxometer multi-aspect survey system developed by Malta-based R3Vox. This partnership marks a milestone in Subsea Europe Services’ commitment to delivering hydrographic survey and underwater inspection technologies to commercial, academic and, through FLANQ, defense customers in the European market.Subsea Europe Services is preparing to take delivery of the most advanced Voxometer-XL system soon, with availability in the company’s rental pool anticipated by the end of summer 2025. Its introduction

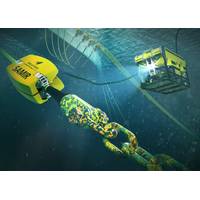

Louis Dreyfus, MaDfly Launch ROV in Open Sea Operations

have deployed a remotely operated vehicle (ROV) in open sea conditions, marking a breakthrough in offshore in-water surveys.The operation was conducted on the service operation vessel (SOV) Wind of Hope next to the Hornsea 2 wind farm in England, marking a significant advancement in offshore inspection technologies.The innovative in-water survey was performed by MaDfly’s expert team under the supervision of the classification society Bureau Veritas.According to LDA, this operation was unique in that it was conducted entirely at sea, without requiring the vessel to halt its ongoing operations

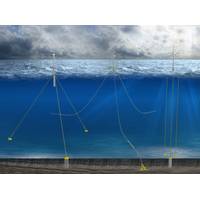

US and Denmark Team Up for $4.2M Floating Wind Innovation Call

500 MW of installed capacity.Novel station-keeping systems and components: Research development, demonstration, or commercialization of technology to prevent failures, decrease costs, improve performance, or increase the capacity of floating offshore wind energy mooring systems.Monitoring and inspection technologies for moorings: Develop sensor systems, remote inspection methods, maintenance strategies, and data collection and processing approaches that can better evaluate the health and reliability of subsea components for commercial-scale floating offshore wind energy arrays. Open Topic: Research

Connecting the Dots: From Remote Operations to Full Autonomy

one offering, enabling users to switch between modes as operations dictate.(Image courtesy Harvest Technology Group Limited) (Image courtesy Harvest Technology Group Limited) The Remote Inspection System (RiS)While it’s difficult to quantify the pace of the transition to remote inspection technologies due to the reluctance of operators to discuss the topic in much detail, the direction is clear: operators are taking people off of rigs and offshore infrastructure and moving to remote options to reduce costs, save time, and minimize safety concerns.To enable this transition Harvest has

Voyis Launches Advanced Vision System for Subsea ROVs

Subsea optical inspection technologies developer Voyis Imaging Inc. has launched a new product line called Discovery Vision Systems that it says will advance ROV vision systems, and deliver a new level of situational awareness to ROV operations, achieving both high-resolution video and real-time 3D perception for piloting, inspection, and autonomy applications. "Subsea inspection operations are a challenging task which have historically required specialized knowledge and complex technology. The growth in ROV (Remotely Operated Vehicles) operations have drastically improved underwater

Tech Files: SmartTouch Helps Detect Oil Pipe Flange Leaks

Seaeye Falcon robot as a development platform.Called SmartTouch, the solution involves integrating innovative robotic manipulator controls into the Falcon that provide multiple stress wave sensors for touch-based inspection of bolted joints, along with the latest structural health monitoring and inspection technologies. Video cameras and scanning sonars are also integrated into the system.Finding a time-efficient and cost-effective robotic solution to identifying flanges at risk was the University’s key objective as bolted flanges can loosen when ocean dynamics shift pipelines. The difficulty of

The Satcom ‘Highway’ will Enable Maritime Digitalization & IoT Solutions

of working to circumvent the fact that they couldn't physically visit vessels, and also that you can change the way you provide your services by the smart use of applications over a digital platform,” touting for instance the fast-track of classification societies’ use of remote inspection technologies.Watch the full interview with Ronald Spithout, President, Inmarsat Maritime, on Maritime Reporter T

ABS: Guidance for Remote Inspection Technologies

Classification society ABS has published new guidance notes detailing best practices for their use on class surveys and non-class inspections.The Guidance Notes on the Use of Remote Inspection Technologies cover pilot-operated unmanned aerial vehicles (UAV), remotely operated underwater vehicles (ROV) and robotic crawlers, collectively known as remote inspection technologies (RIT).“The use of RITs can reduce risk for Surveyors and inspectors by lessening the need to access potentially hazardous locations at height, or other hazardous inspection areas. This guidance facilitates safer, more

Ashtead Technology Acquires Welaptega

offering by adding innovative products, technology and capabilities which are aligned with our current business. “Our customers now have access to a leading innovator in offshore asset inspection, engineering and integrity solutions. Our combined technical capabilities and advanced inspection technologies means we can offer a comprehensive integrity management service to support the performance and life extension of critical infrastructure.”Welaptega's CEO, Tony Hall, will continue to lead the business based in Halifax, Nova Scotia.Hall commented, “Being part of the Ashtead

December 2025

December 2025