Subsea7 Reveals it is Supporting Shell's Vito Waterflood Project

(EPCI) work in the U.S. Gulf of Mexico.The company revealed on social media that the contract was awarded by Shell Offshore Inc., for its Vito waterflood project. Subsea7's work scope includes EPCI of a water injection flowline, hull piping, and associated subsea infrastructure for an enhanced oil recovery project at Shell’s deep-water Vito platform.Project management and engineering work will start immediately at Subsea7’s office in Houston, Texas, and offshore activity is expected to begin in 2026.Shell announced in August it will use water injection to enhance oil volume capacity

Joint Project Set to Improve Oil Recovery from Reservoirs

Fishbones, a provider of alternative reservoir stimulation technology, has started an industry technology development project with major Norwegian operator Aker BP to improve oil recovery from reservoir assets.Supported with a $121,000 (NOK 1.25 million) grant from the Research Council of Norway, the companies will work on the project focused on the development of extended reach needles - small diameter laterals that penetrate the reservoir to increase hydrocarbon recovery.The aim is to extend the reach of existing Fishbones needles by 50%, increasing the current span of 12 meters to 18 meters. Acc

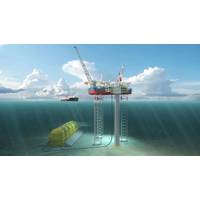

ABS, NOV Collaborating on 'Pioneering' Subsea Storage Solution

, The Research Council of Norway and The Net Zero Technology Centre who are working to enable an economical subsea storage solution for the market.According to the parties involved, the subsea technology brings a new and unique solution for the safe storage of larger volumes of fluids such as enhanced oil recovery (EOR) chemicals, production chemicals, oil, condensate, and maritime fuels. The subsea storage system is being designed to be placed at any water depth and adjusted in capacity depending on customer requirements.ABS NTQ process offers guidance on early adoption and efficient implementation of

Interview: André Lima Cordeiro, Executive Manager, Subsea Systems, Petrobras

did not allow the use of conventional seawater injection plants. In the Barracuda field, the use of a BMHSA with high differential pressure was mandatory to maximize the well oil flowrate, due to the lower efficiency of gas-lift. The main benefits of these systems are maximizing the production and oil recovery.”HISep. Image courtesy Petrobras.HISepBut Petrobras is always looking forward. It’s next milestone in this space is applying its HISep technology. This will be at the Mero field. Cordeiro explains: “HISep is a subsea separation and boosting technology that removes in the seabed

Brownfield Boost: Vigdis Gets a Subsea (Pump) Lift

field. "We have further developed Vigdis in several phases over several years."In December 2018 the license partners – Petoro, Vår Energi, Idemitsu and Wintershall Dea as well as Equinor – decided to invest around $158m in the Vigdis Boosting project, a project for improved oil recovery (IOR), which includes a multiphase boosting station increasing production from existing wells. This pump came on stream in May 2021.Connected to the existing pipeline between Vigdis and Snorre A, the boosting station helps bring the well stream from the subsea field up to the platform. In addition

Subsea Tiebacks: A Troll with a Kinder Surprise

in place today, as there is no access now.”Troll Phase 3 beneath the surface. Source: Equinor.Contracts and operationsTroll Phase 3 was approved in 2018. It will see the gas cap on Troll west finally developed. It had been deliberately held back to balance and stabilize the oil column, so that oil recovery at Troll West Could be maximized.Aker Solutions was awarded the contract for the subsea production systems, Nexans was contracted for 27km of umbilicals with power, fiber optic and hydraulic cores, as well as a MEG services line for chemical injection. DeepOcean was contracted for marine operations

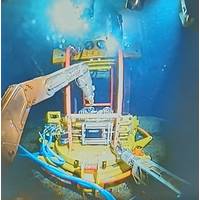

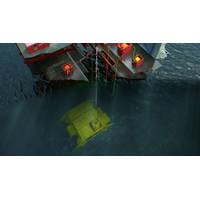

'Attic' Oil Removed from Shell Bravo Concrete Storage Cell

us to optimize this same low-risk system, specifically for working from a vessel, yielding significant operational efficiencies, and increasing value to our client. As a result, we now have extended the track record of the only field proven system, which can be configured to suit a variety AOR (Attic Oil Recovery) decommissioning programs.”Roy Nilsen, DeepOcean project manager said. “The attic oil recovery project on Shell’s Brent Bravo platform was a great project for DeepOcean and its success comes from the combination of Enpro Subsea’s F-Decom system and DeepOcean’s expert

Aker Solutions Develops Faster Offshore Well Workover System

delivered in the spring of 2021 to perform intervention operations on Visund.The Visund field northeast of Gullfaks has a water depth of 335 meters and 23 Aker Solutions subsea trees installed. Interventions will play an increasingly important role operationally in the future for Visund to increase oil recovery, Aker Solutions said

Subsea Robots in the Splash Zone

subsea workshop,” Schjetne says among the mostly dank recesses.The former anchorages, from four to eight meters deep, are crammed with training platforms and testing equipment. IMR tools are in increasing demand, as offshore operators and their contractors look to extend field life and increase oil recovery. This is where OceanTech’s prototype, all-electric iCon inspection robot was tested for its ability to lower itself and its probes below the splashzone to effect subsea inspections of … you name it: pipe, riser, concrete or jacket. The iCon is the latest in a series of about five

December 2025

December 2025