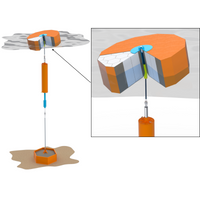

EU Grants $2.7M for Research Into Novel Concrete Materials for Offshore Renewables

proof-of-concept from a previous project (WECHULL), where a new, highly flowable high-performance concrete mix was developed for Ocean Harvesting’s patented thin-walled honeycomb buoy.The solution enables large scale production on site and results in a buoy with a weight similar to a conventional steel hull, but with significant reduction in cost, CO2 footprint and manufacturing time..Mikael Sidenmark, CEO Ocean Harvesting Technology, said: “Reducing the use of resources and the environmental impact are critical in the energy transition. We are very pleased that our honeycomb design for floating

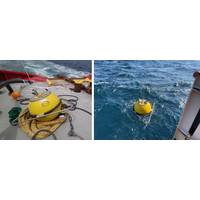

Navigational Hazard: Wave Buoy Breaks Free from Mooring at West of Orkney Wind Farm Site

wave buoy is located at: 59° 26' 45.0"N 4° 17' 39.9" W – 07:30 UTC 11/04/2023," notice to mariners read on Wednesday.The unit that broke free is a Datawell Wave buoy measuring directional waves, temperature and current. It is yellow, weighs 250 kg, and its stainless steel hull is one meter in diameter with an aluminum triangle. OWPL, a consortium of TotalEnergies, Corio Generation, and RIDG, has been in contact with a vessel contractor who is currently preparing a vessel to perform both the recovery and re-deployment as soon as possible.The West of Orkney Windfarm

Eni Installs "World's First" Inertial Sea Wave Energy Converter Offshore Pantelleria

. ISWEC design can be optimized with reference to the metocean conditions of the site where it is installed by means of a genetic algorithm that leverages on the significant computing power of Eni’s Green Data Centre (GDC) based in Ferrera Erbognone, Eni said.The machine consists of a steel hull measuring 8 x 15m which houses the energy conversion system, consisting of two gyroscopic units, each more than 2m in diameter. The device is held in place in a 35m deep seabed by a special mooring system that responds to weather and sea conditions, consisting of three mooring lines and a swivel

Kongsberg to Equip Three Polish Navy Warships with Hugin AUVs

of underwater positioning and navigation systems. This allows for high-accuracy position updates for the vehicle, as well as real-time communications for status, sensor quality assurance and on-the-fly mission replanning," Kongsberg said.According to defence publication Janes, the non-magnetic steel hull Kormoran II class is designed for minehunting in Poland's exclusive economic zone (EEZ), with task forces in the Baltic and North seas. The vessels are intended to provide substantial increase of Polish MCM capabilities, doubling the number of existing Kormoran II type vessels in service, to

Ocean Harvesting's Wave Energy Converter to Feature Buoy Made of High-strength Concrete

undergo sea trials later this year.According to the company, the buoy system is being developed using high-strength concrete with low environmental footprint and excellent durability. "The solution allows for large-scale production and results in a buoy with a weight similar to a conventional steel hull, but at 1/4 of the cost and 1/3 of the CO2 footprint," Ocean Harvesting said.Describing the process, Ocean Harvesting said: "Highly flowable concrete is poured into a mold with void fillers, forming the concrete shell and the internal honeycomb structure, one of the strongest structures

FRV for Bangladesh

. Outside on the forecastle deck are the hydrographic winch and associated control station, plus a 4.2m Hwayan rigid inflatable work/rescue boat and associated davit. Meen Shandhani is classed by Bureau Veritas with I * Hull *Mach Special service / Research shipUnrestricted Navigation. Its steel hull has a molded beam of 9.2m, depth of 4.6m and design draft of 3.3m corresponding to a deadweight of just over 194 tons. It is expected to commence extensive fisheries resource surveys in the Bay of Bengal. (As published in the October 2016 edition of Marine Technology Reporter

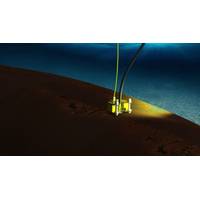

New Tool Recovers Oil from Sunken Wrecks

Options include sealing the wreck or recovering the pollutant in a controlled manner, which Moskito seeks to do. How it Works Moskito is able to be deployed by divers or by an ROV to any ocean depth. Once in position outside the tank the Moskito’s three magnetic feet are planted against the steel hull and a technician on the surface activates a 75 mm (3-inch) diameter electrically powered tank cutter drill. With its operation controlled through a dual video link, the Moskito’s drill pierces the steel tank walls which may be up to 40 mm (1.5-inches) thick. The cut disc then falls away inside

Moskito to Recover Oil from Sunken Wrecks

include sealing the wreck or recovering the pollutant in a controlled manner, which Moskito seeks to do. How it Works Moskito is able to be deployed by divers or by an ROV to any ocean depth. Once in position outside the tank the Moskito’s three magnetic feet are planted against the steel hull and a technician on the surface activates a 75 mm (3-inch) diameter electrically powered tank cutter drill. With its operation controlled through a dual video link, the Moskito’s drill pierces the steel tank walls which may be up to 40 mm (1.5-inches) thick. The cut disc then falls away inside

New Tool for Recovering Oil from Sunken Wrecks

to recover the pollutant in a controlled manner. The Moskito makes this possible through being able to be deployed by divers or by an ROV (Remotely Operated Vehicle) to any ocean depth. Once in position outside the tank the Moskito’s three powerful magnetic feet are planted against the steel hull and a technician on the surface then activates a 75 mm (3-inch) diameter electrically powered tank cutter drill. With its operation controlled through a dual video link, the Moskito’s drill pierces the steel tank walls which may be up to 40 mm (1.5-inches) thick. The cut disc then falls away

August 2025

August 2025