Sonardyne Introduces New Hybrid Acoustic-Inertial Navigator

north seekingSurvey-grade performanceExtended altitude rangeRapid deploymentEasy operationSPRINT-Nav U is particularly valuable for offshore wind operations, where its compact FOG-based IMU provides continuous, high-accuracy position, orientation, and velocity data even when operating in and around steel structures. This capability enables operators to conduct thorough inspections of wind turbine foundations, cables, and other subsea infrastructure without the interference issues common to magnetic-based systems

Innovative ‘Wall Climbing Robot’ for Ship Inspection Earns ClassNK Endorsement

The wall climbing robot for steel structures - developed by Mitsui O.S.K. Lines, Sumitomo Heavy Industries, and MOL Ship Management to support ship inspection and maintenance - has completed a demonstration test and earned the Nippon Kaiji Kyokai (ClassNK) Innovation Endorsement.The Innovation Endorsement is ClassNK's third-party certification program. It certifies and supports initiatives that contribute to the sustainable evolution of maritime and offshore businesses.The robot developed by Japanese partners is characterized by its high traversability not only on vertical walls but also on

First OSS for 2.6GW US Offshore Wind Project Arrives to Denmark

for the 2.6 GW offshore wind project.Bladt, Semco to Deliver Three 880MW Offshore Substations for CVOW ProjectThe scope of work on the project includes design, engineering, procurement, manufacturing and installation. Bladt Industries is responsible for design, procurement and manufacturing of steel structures and jacket foundations, while design, procurement and installation of electrical equipment, emergency systems and inter-array cables will be managed by Semco Maritime.The project, located approximately 23.5 nautical miles off Virginia Beach, has been approved for construction and operation by

EU Grants $2.7M for Research Into Novel Concrete Materials for Offshore Renewables

wave energy developers Carnegie Clean Energy, and Ocean Harvesting Technologies, as well as floating solar company Solar Duck.Concrete structures are said to be low cost, resistant to the marine environment, and are easy and fast to manufacture on-site, in comparison to manufacturing of traditional steel structures.The solutions developed in the WECHULL+ project regarding material, modelling and design will be applicable for floating structures in ocean renewables and other areas.WECHULL+ is based on the results and proof-of-concept from a previous project (WECHULL), where a new, highly flowable high-performanc

Odfjell Oceanwind aims to Help Decarbonize Offshore Drilling with Floating Wind

Drilling to be able to drill wells with zero emission, and having MOWUs was one way for us to get there. We have access to all the [Odfjell Drilling] experience, all the harsh environment, all the engineering expertise, when it comes to all facets of designing, owning, operating harsh environments, steel structures. So we can piggyback on all that learning.What are the financial drivers to adopt this technology?In Norway, the authorities have said that the companies that emit pay high CO2 taxation. The intention is to create a positive business case for making these investments. So in Norway, there is

XLCC to Order New Cable Laying Vessel

and future void in the market.”XLCC said it has teamed up with Salt Ship Design to develop the basic design of the vessel while working toward the selection of a shipyard to build it. The design has been developed from basic design stage in 3D engineering software for best definition of steel structures and interiors arrangement, the company added. Operational aspects of the cable handling have been studied in collaboration with MAATS Tech and Global Marine.Tor Henning Vestbøstad, sales director of Salt Ship Design, said, “The design is now matured to the level ready for pricing

Nova Innovation to Develop 15MW Tidal Array at Yell Sound, Shetland

world-leading project.”"Nova said it has been using has a strong track record and has delivered positive impacts for the local community including the use of highly skilled local companies and local manufacturing and fabrication. Companies in Shetland currently manufacture blades, steel structures and provide vessels and services for Nova. The turbines will be manufactured at Nova’s facility in Edinburgh," the company said.Nova’s tidal turbines sit on the seabed, so there is no visual impact on the land and seascapes of Shetland, with ships free to pass above them. Comprehensi

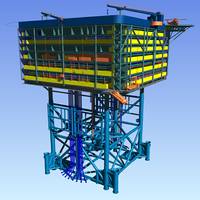

Trelleborg Wins Floatover Installation Contract for BorWin3

have been contracted to supply six sets of leg mating units and the same amount of deck support units.” Trelleborg’s leg mating units (LMUs) make a floatover transition possible by damping the forces created as the topside’s load is transferred to the jacket. Consisting of steel structures filled with elastomeric pads, the LMUs are designed to take up the static and dynamic forces of the topside structure, as well as the horizontal forces due to open sea motions during installation. The assembled LMU can be installed either on the topside or substructure. In addition, deck support

Foster Wheeler Wins Contract For Retrofit-SCR System

2014. Commercial operation of the SCR system is scheduled for October 2015. Foster Wheeler will design, supply, erect and commission the selective catalytic NOx reduction system for the Naantali 125 MWe pulverized coal fired boiler (unit 3). The supply includes a new SCR reactor with catalyst and steel structures, ammonia water storing and feeding system, flue gas ducts and new ID-fans. “This retrofit-SCR project awarded in Europe is indicative of Foster Wheeler’s competitiveness in environmental technology in the region,” said Tomas Harju-Jeanty, Chief Executive Officer of Foster

August 2025

August 2025