Saipem’s Castorone Vessel on Its Way to Türkiye’s Largest Gas Field

to operate in multiple scenarios, Castorone can lay pipelines in S-lay configuration in both shallow and deep waters, up to 3,000 meters. It features a Class 3 dynamic positioning system with eight thrusters, ensuring precise operations even in adverse weather conditions. Its adjustable 120-meter-long stinger and tensioning capacity of up to 1,200 tons allow it to handle pipelines with diameters of up to 60 inches, making it ideal for large-scale projects.The vessel’s technological systems include advanced welding equipment and two remotely operated vehicles (ROVs). These ROVs, developed by Sonsub

TDI-Brooks Completes Phase Four of Deepwater Geotechnical Project in Black Sea

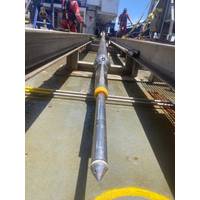

TDI-Brooks said Thursday it had completed phase four of a deepwater geotechnical coring and CPT project for DenAr Ocean Engineering S.A. TDI-Brooks used its Jumbo Piston Cores (JPC) and CPT Stinger geotechnical tools and operators to the ongoing project off Turkey in the Black Sea.The PROTEUS is outfitted with TDI-Brooks’ complete geotechnical tool kit, including a suite of innovative geotechnical tools for soil sampling and CPT measurement. The PROTEUS also has a Kongsberg EM-710 (1×1) hull-mounted multibeam (MBES) for surveys to ~2,500m water depth for performing surface geochemical

Equinor to Test Autonomous Robots for Subsea Leak Detection

Equinor is set to trial the use of autonomous robots for subsea leak detection services in the North Sea.The Norway-based energy company has tapped Houston's Nauticus Robotics and its Norwegian technology partner Stinger Technology for the pilot project. The companies did not say where and when the tests would be performed.Nauticus, a developer of ocean robots and artificial intelligence for autonomous services, said the pilot aims to validate the its technology and provides an opportunity to qualify for future contracts with Equinor, the leading operator on the Norwegian continental shelf with a

TDI-Brooks Adds 75m DP2 Ship to its Fleet

tool kit including a suite of innovative geotechnical tools for soil sampling and measurement. These include 0.5 and 1 meter box corers (BC), 6 and 9 meter piston corers (PC), 20 meter jumbo piston corers (JPC), cyclic t-bar instrument (TBAR), piezocone penetrometers including a 40 meter CPT-Stinger and 10 meter Gravity CPT tool (gCPT), newly acquired Geomil Manta-200 CPT, Neptune 3K & 5K vibracorers and TDI-Brooks’ designed pneumatic vibracorer. The Nautilus will have a Teledyne RESON full ocean depth multibeam echosounder (MBES) for surveys to ~2,500m water depth for performing

Subsea Robotics: Aquanauts, Hydronauts, Roll Out

;t really any electric manipulators in the market, so we decided to fill that gap made our first delivery to IKM (in Norway).” That’s been through some development work with IKM and now the first production batch has now started, he says.Earlier this year the firm also agreed to work with Stinger AS, a specialist underwater technology firm, also in Norway. The details of that are being worked on, says Radford. Nauticus also had an agreement with Triumph Subsea, a new company that had announced various plans for a new breed of greener offshore vessels. There is still a contract with them

Kongsberg to Equip Three Polish Navy Warships with Hugin AUVs

imagery and bathymetryKONGSBERG EM2040 Multibeam Echosounder, an industry standard bathymetric mapping sonarUHD Colour Camera with LED Lighting Panel for high-resolution optical imageryForward-looking Sonar and altimeters for obstacle avoidance and trajectory planningLow magnetic-signature stinger launch & recovery system (LARS)KONGSBERG Sunstone advanced Inertial Navigation System (INS) for industry leading autonomous position accuracy"Capable of fully autonomous operations without surface vessel support, HUGIN is also designed to work in conjunction with the HiPAP (High Precision

Edward Heerema – Dutch Courage with Single-minded Focus

Spirit wind installation concept. Photo courtesy AllseasThe new jacket lift systemAllseas will soon be targeting more and larger jackets with its new 25,000-tonne jacket lift system (JLS). The JLS was initially planned to be added to the vessel in 2016, but pipelay work with the vessel’s massive stinger took precedence and since then fabrication delays and COVID have also taken their toll. However, it’s now almost ready for its first project. The system has two, aft-mounted 170m-long lifting beams used to lift then upend jackets onto the vessel’s deck, with the jacket then resting on

TDI-Brooks Completes Geotechnical Program in GOM

Exploration & Production LLC in the deepwater Gulf of Mexico. The project consisted of ‘heavy’ geotechnical coring/cone penetration testing (CPT) with TDI-Brooks’ research vessel, the R/V Gyre. The project included the acquisition of 20-m Jumbo Piston coring, 40 meter CPT-Stinger samples and 40 meter Shelby-tube Stinger samples. Other piston, box core and gravity CPT (gCPT) samples were acquired associated with oil and gas export pipelines.The Shenandoah field development project is located in the Walker Ridge (WR) area in water depths ranging from 5,800 to 6,300 feet. The

New Report Tracks Sources of Marine Litter

is a need for a better understanding of the presence of plastics in wastes dumped at sea, both in terms of the characterization of the plastics present as well as the geographical distribution.Other ocean uses: marine litter can occur as a result of offshore oil and gas exploration; shark and "stinger" nets set up in beach areas to prevent harm to humans; weather monitoring, which can create debris, such as weather balloon equipment including acidic batteries, plastic components and latex rubber; artificial reefs, which may be constructed out of waste materials such as old tyres, etc and

December 2025

December 2025