Floating Wind and the Taming of Subsea Spaghetti

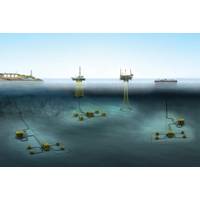

planned to be carried out by Windstaller Alliance, an alliance between Aker Solutions, DeepOcean and Solstad Offshore.The system itself was developed following the proven success of similar technologies in large installation projects, Aker Solutions’ experience in subsea power solutions for subsea gas compression and more recently for floating offshore wind like Equinor’s Hywind Tampen.While having technology such as transformers subsea comes with cost considerations, he cites the O&G trend to have more infrastructure subsea including projects such as Åsgard and Jansz-lo.In fixed offshore

Subsea Digitalization: Remote Control

The more production infrastructure we push to the seabed, the more data we need to pull back up. With it comes opportunity.Chevron’s landmark 6,500 tons of subsea gas compression infrastructure for Jansz-Io demonstrates the scale of what is being put on the seabed, but there’s a diversity of other infrastructure under development that will operate alongside traditional production systems.This includes subsea fluid storage technology from NOV Subsea Production Systems, and TechnipFMC and Sulzer Flow Equipment’s subsea CO2 pumps for new high pressure separation technology

Chevron Taps ABL for MWS at Jansz-Io Compression Project in Australia

four work packages. The work packages relate to the offshore installation, construction, and marine transportation operation of the field control station and high-voltage power and communication transmission system, plus marine transportation of other high value and general project cargo.The subsea gas compression technology used at the Jansz-Io field will improve natural gas recoverability and supply to the Barrow Island gas processing facilities, ensuring Gorgon continues to deliver vital natural gas to customers in Western Australia and Asia for decades to come.The Jansz–Io gas fields are

Aker Solutions to Deliver Subsea Umbilical for Chevron's J-IC Project Off Australia

Norwegian offshore energy equipment supplier Aker Solutions has won more work at Chevron's Jansz-Io subsea gas compression development, offshore Australia.After it in July secured a contract to deliver the subsea compression system for the project, Aker Solutions has now won a deal to deliver the dynamic subsea umbilicals for the offshore gas compression development.Under the contract, Aker Solutions will be responsible for the engineering, design, and manufacturing of a total of about 70 kilometers of dynamic subsea umbilicals. The scope of work includes three subsea compressor umbilicals, two

Aker Solutions Confirms Major Subsea Compression Contract with Chevron

Norway's Aker Solutions confirmed Tuesday it had secured a "major contract" from Chevron to provide a subsea gas compression system for the Jansz-Io field, offshore Western Australia. The contract follows Chevron's sanction of the $4 billion project last week. Aker Solutions said last week its subsea compression tech had been selected for Chevron's Jansz-Io Compression Project, but that the companies were in ongoing talks to finalize the contract.The confirmation came Tuesday when Aker Solutions said it had won the deal and had booked around NOK 7 billion ($815,59 million)

Offshore Energy Outlook for 2020

and unmanned platforms are also high on the agenda, including that of Norway’s largest oilfield services company Aker Solutions, who announced in October that it aims to generate half of its revenue from renewable energy and low-carbon technologies (such as carbon capture and storage, subsea gas compression, floating wind farms, electrification, etc) by 2030.Equinor’s Hywind Tampen project will use floating wind turbines to provide power to the Snorre and Gullfaks oil and gas production facilities. (Image: Equinor)A lot of hydrocarbonsIn October 2019, the mega Johan Sverdrup field

Partners Target Subsea Gas Seperation

qualities that are suitable for bulk separation of CO2 in a typical subsea process, and confirm technical and economic use of subsea processing as a favorable concept for the realization of offshore CO2 EOR in combination with reinjection and storage of CO2.Aker Solutions delivered the first subsea gas compression system to Equinor for the Åsgard field offshore Norway. The system has been in operation with no unplanned downtime since it was installed in 2015. The subsea gas separation technology in combination with the subsea gas compression technology could make offshore handling of CO2 for

Aker Solutions Eyes Low Carbon Tech

Sea."Growth in segments such as renewables and CCUS increases the addressable market for Aker Solutions," Araujo said. "Our ambition is to become the recognized leader in low carbon offerings and sustainable solutions."Other low carbon technologies such as solutions such as subsea gas compression and electrification of production assets and unmanned platforms are also high on the company's agenda.Aker Solutions delivered the world’s first subsea gas compression system to Equinor’s Åsgard field in 2015. The company is currently involved in developing the first

Interview: Woodson Ferreira, Aker Solutions, Brazil

;s original expertise in subsea operations came from the challenges of developing the deep waters and complex reservoirs of the North Sea, where Aker Solutions was one of the original companies installing subsea equipment and developing subsea systems. In 2015, it delivered the world’s first subsea gas compression system for Statoil’s Åsgard field in the Norwegian Sea, about 200 km off the coast. The system, nearly the size of a football field, revolutionized offshore natural gas production by cutting costs and improving safety with fully-fledged oil and gas production and processing

December 2025

December 2025