TechnipFMC Awarded Hammerhead Contract

TechnipFMC has been awarded a substantial ($250-500 million) contract by ExxonMobil Guyana Limited to supply subsea production systems for the Hammerhead development in Guyana’s Stabroek Block.TechnipFMC will provide project management, engineering, and manufacturing of subsea production systems supporting both production and water injection capabilities. The subsea architecture will include products from the Subsea 2.0 ® platform, including subsea trees, manifolds, and associated controls.Jonathan Landes, President, Subsea at TechnipFMC, commented: “Hammerhead is our seventh greenfield

Reach Subsea Completes Inspection for TotalEnergies Using USV/ Electric ROV

Reach Subsea has completed a subsea inspection campaign for TotalEnergies, carried out in the Skirne, Byggve, and Atla fields on the Norwegian Continental Shelf.The project was delivered using Reach Remote 1, an unmanned surface vessel equipped with an electric ROV.The annual inspection covered subsea production systems and Xmas trees, including integrity checks, assessment of anode status, and seabed condition surveys. In addition, extended survey work was undertaken to support preparations for the upcoming decommissioning campaign.“Using Reach Remote 1 allowed us to perform the inspection safely

Trendsetter Secures 15K Subsea Tree Contract

to a major Gulf of America operator. This contract represents a significant milestone for Trendsetter, coming immediately on the heels of its recent expansion into the subsea tree market.With the recent acquisition of the Innovex subsea tree product line and installed base, Trendsetter’s subsea production systems capabilities now encompass the production flow-path from the subsea tree, through the riser system connected to the host production facility. Trendsetter’s goal is to deliver customer-led subsea project solutions that are tailored to maximize our customer’s ability to reliably

Scana’s Subseatec Hooks Supply Deal for Subsea Production Systems

Scana-owned Subseatec has signed a frame agreement with an international company within subsea technology to act as its exclusive global supplier of steel parts for subsea production systems.The frame agreement will begin in the first quarter of 2025 and extend for a period of three years.The frame agreement does not entail a minimum delivery obligation but based on historical revenues related to the client and an expected pipeline over time, Scana expects the volume to be classified as a sizeable contract.For Scana, this means the contract value is between $2.2 million and $6.6 million.“The

Vår Energi Pre-Orders Subsea Systems to Accelerate Oil and Gas Developments

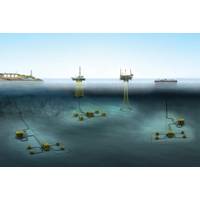

Norwegian oil and gas company Vår Energi has signed a letter of intent with OneSubsea for the delivery of Subsea Production Systems (SPS) to reduce project development time. The pre-commitment will give Vår Energi the ability to shorten subsea tie-back development time by up to one year. The pre-commitment agreement comprises a complete Subsea Production System, which include a standard four-well slot template and a single well satellite structure. The order is to be delivered prior to summer 2027, while parts necessary for drilling will be delivered in 2026.Further, the

Subsea Digitalization: Remote Control

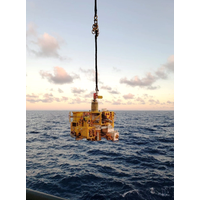

gas compression infrastructure for Jansz-Io demonstrates the scale of what is being put on the seabed, but there’s a diversity of other infrastructure under development that will operate alongside traditional production systems.This includes subsea fluid storage technology from NOV Subsea Production Systems, and TechnipFMC and Sulzer Flow Equipment’s subsea CO2 pumps for new high pressure separation technology from Petrobras.Chevron’s landmark 6,500 tons of subsea gas compression infrastructure for Jansz-Io demonstrates the scale of what is being put on the seabed.Photo:

New Project Marks Tipping Point for Subsea Electrification

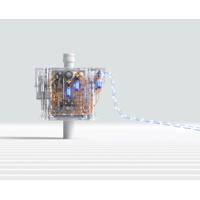

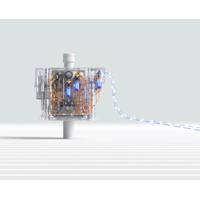

have been made across the industry to make this capability a reality, and we now see several projects on the horizon that use all-electric as their base case.”The first project is the recent contract award from Equinor for the front-end engineering design (FEED) of a 12-well, all-electric subsea production systems project in the Fram Sør field, offshore Norway. The solution will use SLB OneSubsea’s standard subsea tree design, upgraded with a fully electrified power, control and actuation system.“You can only go so far by optimizing component-level performance,” says Macleod

SLB OneSubsea to Design All-Electric Subsea System for Equinor’s Fram Sør Field

Oilfield services company SLB has, through its joint venture OneSubsea, secured a contract from Equinor for the front-end engineering design (FEED) of a 12-well, all-electric subsea production systems project in the Fram Sør field, offshore Norway.The project could help fast-track wide-scale global adoption of electric subsea technology, setting new standards for increased operator control, subsea operational efficiency and reduced offshore emissions.As part of the agreement, future engineering, procurement and construction will be directly awarded to SLB OneSubsea conditional on a final

OneSubsea Scoops 'Sizeable' Contract for Work at Troll Gas Field in North Sea

project partners earlier on May 24, 2024.Equinor and Partners Invest Over $1.1B in Troll Gas Field’s New InfrastructureTo accelerate field delivery of the subsea tieback to existing infrastructure, SLB OneSubsea will leverage configurable solutions compliant with NCS2017+ for standardized subsea production systems for application in the Norwegian Continental Shelf (NCS).The objective for Troll Phase 3, Stage 2 is to accelerate production from the reservoir equivalent to about 55 billion standard cubic meters of gas.“We deeply appreciate our long-standing relationship with Equinor, and we look

December 2025

December 2025