LOTOS Petrobaltic Selects Saab Seaeye Leopard ROV for Subsea Work in Polish Oil Fields

configuration includes a Sonardyne DVL/INS survey system, Sprint-Nav INS, Digital Edge recording and event system, five cameras including Kongsberg HD system, also a One Laser for video and measurement, Tritech Super Seaking sonar, a seven-function manipulator, Schilling Orion gripper, electric torque tool, rotary disc cutter, WeSubsea dredge system, FlexiClean cleaning tool, water jet system and caviblaster, Cygus ultrasonic thickness gauge, multiplex survey pod and tooling sled.The Leopard package also includes a tophat tether management system (TMS), an ‘A’ Frame launch and recovery

Subsea IMR Moves Robotic

further testing and configuration trials in Trondheim later this year, it is planned that the first two subsea-resident Eelume systems will be deployed on the Åsgard subsea production field for Equinor. The two robot systems will be configured for inspection duties and intervention tasks, including torque-tool valve operations. These first subsea-resident Eelume systems will operate in battery-powered, tethered control mode, but before the end of the year are expected to demonstrate tetherless operations.Credit: EelumeStaying “Connected”To support widespread tetherless operations of AUVs

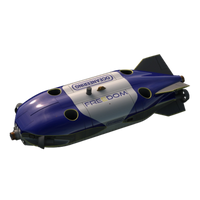

Valeport Sensor Technology for Freedom ROV/AUV

;s compact and robust environmental monitoring sensor, the Hyperion Fluorometer, for the high performance measurement of Chlorophyll A.Oceaneering’s Freedom ROV aims to offer a new level of flexibility and efficiency while performing common ROV tasks including survey, inspection, valve and torque tool operation, manipulator-related activities and underwater inspection in lieu of dry docking operations. It operates in tethered and autonomous tetherless modes

MTR100: Five "Ones to Watch"

alternatives ranging from 50W to 2.3kW, all with ethernet and serial communication speeds up to 80 Mbps and 230kbps respectively. It’s also working on a next generation 9.2kW connector, as well as other types of mechanical and hydraulic connectors for drones.Blue Logic has also developed a new torque tool for AUVs and ROVs. Its previous torque tool weighed 23kg in water, which would have been too heavy for a vehicle like the Eelume snake robot, says Helge Sverre Eide, Blue Logic’s business manager. So engineer Lars Gunnar Hodnefjell worked on a lighter version - 7.5kg in fact (improving the

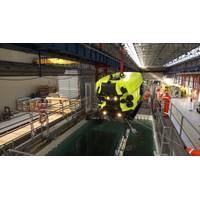

Seaspace Race Underway at Saab Subsea Docking Demo

the need for humans and vessels offshore. “We can design fields in different ways then as could increase production efficiency. It’s profitable in remote areas.”Saab Seaeye’s Sabertooth can operate as an AUV but is also able to hold station to use tooling. In fact, an electric torque tool was fitted on the vehicle during the trials and Saab Seaeye is testing an electric T4 equivalent manipulator. Autonomous docking to the SDS would also be possible, said Saab Seaeye, just as it does with its own docking station.(Photo from Saab Seaeye)Following the trials, the SDS is going to be

Sonardyne Equips Latest Oceaneering Vehicles

will be based out of docking stations on the seabed, enabling it to recharge and download data before and after its subsea inspection, maintenance and repair missions. It will operate in tethered and autonomous tetherless modes, performing both AUV and ROV related tasks, including survey, inspection, torque tool operation and manipulator-relator activities.Oceaneering Jami Cheramie, “Both of these systems have been developed to drive a step-change in inspection, repair and maintenance operations in subsea oil and gas fields, to help both increase uptime, operational flexibility and autonomy. A single

Smart Torque Tool Takes Off

Considerable savings in major torque intervention projects are reported by five subsea operators who were early to adopt the new smart electric torque tool from TMT and Saab Seaeye and is now available as a rental option.Offshore operator, McDermott, found it could get a rapid configuration change to their electric tool with accurate torque operations and speeds up to 30 rpm, operating eight valves requiring 90 to 107 turns each. At an optimum time of 10 minutes per valve, considerable vessel time was saved.Sold in the northern hemisphere by Saab Seaeye, a manufacturer of electric underwater e-robotic

Unmanned Vehicles May Soon Take Up Residency Subsea

a Sabertooth, for recharging and communications, in an indoor tank before going offshore to an Innogy-owned wind farm, Gwynt y Mor.In AUV mode, the Sabertooth has already done multibeam echosound pipeline tracking, magnetometer/gradiometer pipeline tracking and bottom sediment sampling. An electrical torque tool and an Orion a sensor for detecting buried pipeline or cable tracking have also been developed.Saab Seaeye also has plans for autonomous contactless cathodic protection measurements, using field gradient sensor technology. It’s also working on autonomous structure inspection and riser/umbilical/m

Smart Torque Tool Advances an Electric Future

A breakthrough in electric torque tool technology is set to further advance the capability of electric underwater robotic vehicles, says Saab Seaeye. The electric underwater e-robotic systems manufacturer has collaborated with Australia-based Total Marine Technology (TMT) to launch a new lightweight electric torque tool that is smart, light, simple to fit, fast to set up, has an advanced, high accuracy torque control system and can operate across the Saab Seaeye range of e-robotic vehicles, opening up new market opportunities. Considerable savings will come from using compact electric

August 2025

August 2025