The story has been removed

Sorry for inconvenience

Related News

Fincantieri Launches Italian Navy’s Hydro-Oceanographic Ship

Fincantieri has launched Italian Navy’s newly built hydro-oceanographic ship (N.I.O.M.) Quirinale at its integrated shipyard in Riva Trigoso…

Study: Low Sulfur Fuel Reduces Lightning, May Increase Temperatures

Cuts in sulfur emissions from oceangoing vessels have been tied to a reduction in lightning stroke density along heavily…

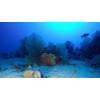

New Project to Assess Resilience of Mesophotic Coral Reefs

Scientists are to carry out an assessment of the response and resilience of mesophotic coral ecosystems – coral reef communities…

IMO Welcomes First Global Marine Biology Treaty in International Waters

The world’s first global treaty to protect ocean life in international waters enters into force on January 17, 2026, bringing…

Subsea Cable Risk a Mix of Bathymetry and Geopolitics

A new study undertaken by a group of researchers from the UAE, Canada, Japan, and Taiwan collates a range of statistics and…

The French Hydrographic & Oceanographic Service Orders New Maritime Drone

Following a seven-month bidding process, the French Hydrographic and Oceanographic Service (Shom) placed an order at the…

Featured Companies

Tethys Robotics

Yacht Signs

R.M. Young Company

Harvest Technology Group

Advanced Navigation

MetOcean Telematics

December 2025

December 2025