CMS-Geotech Launches New Monitoring System

Vibrocoring is an established fundamental phase of marine seabed investigations, but it’s importance is often underestimated, and much vibrocoring is carried out somewhat blindly, ie lowering the unit to the seabed, vibrating for a set time and recovering to the surface in the hope that an adequate sample has been obtained.

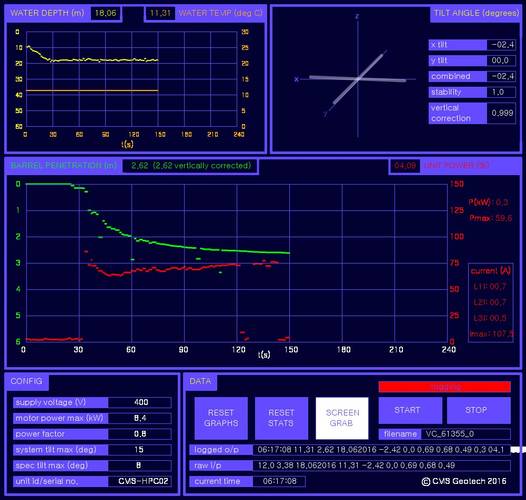

- frame inclination – vital for both when there is a maximum deviation angle specified for engineering purposes and improved safety against slope instability in areas of soft muds or shifting sands and falling over due to tidal current forces

- barrel penetration – real-time indication of penetration distance and rate of advance enables operator to stop the test when no useful penetration is being gained minimizing sample disturbance and maximize sample integrity. Reduction in lost seabed bottom time improves the operational cycle time with associated cost saving implications.

- power consumption – logging of power consumption indicates relative difference between different strata in different locations due to insitu strength and particle characteristics

- live video feed of core barrel penetration and seabed conditions where conditions allow

All data is logged continuously and provides the client with reassurance that the best possible test was undertaken and test cessation was for a specific and identifiable reason. The impact of varying the frequency can also be assessed.

December 2025

December 2025