Pipeline to Carry Water from Turkey to Cyprus

A transnational water pipeline is being built to provide a supply of fresh water from Turkey to Cyprus. MacArtney was contracted by AES and I4O to provide the underwater connectivity solutions for various instrumentation systems mounted on the pipeline.

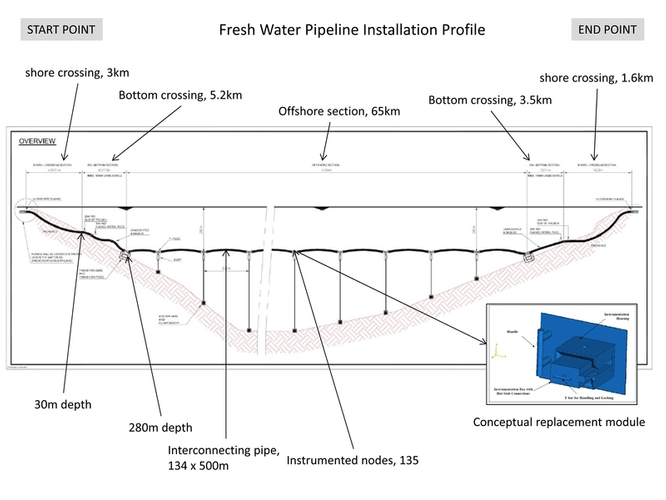

In the first such project in the world, Turkey will soon be able to pump water directly to northern Cyprus with the help of an 80-kilometer water pipe running under the Mediterranean Sea at a depth of up to 280 meters. The pipe will be buried for the first 3 kilometers, lay on the bottom for the next 5 kilometers, be suspended offshore for 65 kilometers, lay on the Cyprus-side seafloor for 3.5 kilometers and then be buried again for 1.6 kilometers.

Symbolically named Baris Su (Peace Water), the project will bring 75 billion cubic meters of fresh water a year from the Turkish river of Anamur to Cyprus. About half of the water will be used for agricultural development and the other half as drinking water. While the immediate aim is to provide water for the Turkish sector of Cyprus, authorities in Turkey insist that the Greek Cypriot administration in the south of the island can also benefit from the fresh water pipeline - and this could prove to be a catalyst in the ongoing Cyprus peace talks. Furthermore, Ankara hopes the technical knowledge gained in the course of the project could enable Turkey to export water and even hydrocarbons to countries in the Middle East.

MacArtney has supplied SubConn connectors to interconnect 145 cables of approximately 1,000 meters length which will be attached to the water pipe. At 1,000-meter intervals, MacArtney have built special interconnect ‘T’ assemblies to interface the ends of the cable and to attach sensors for measuring water pressure and other parameters. In addition to the cable interconnects and assemblies, MacArtney also provided 50 water blocked SubConn penetrators molded to pipe-attached transponders intended to warn submarines of the presence of the pipeline.

Within the scope of the project, MacArtney said its technicians have had to perform complex and challenging molding to two versions of cable - an armored cable used for the shore crossing and a non-armored cable used for balance. Both cables have Polyethylene (PE) and Polyurethane (PUR) jackets. The PE jacket requires the mastery of special molding techniques to ensure a water tight bond. MacArtney designed and developed special bonding for SubConn 10 pin Micro and Standard Circular connectors for this program - with the terminations and assemblies being done at the workshop in Houston.

December 2025

December 2025