Carnegie Launches Wave Energy Device to Power Moored Vessels

Carnegie will design, install and operate a scaled demonstrator of the MoorPower technology just offshore from its headquarters and research facility in North Fremantle, Western Australia. Carnegie's CETO Technology - Credit: CarnegieThe project's academic and industry partners include DNV GL Australia, Advanced Composite Structures Australia, University of Tasmania, Climate KIC/Australian Ocean Energy Group, AMC Search, and the University of Queensland. The project is supported by $1.35m cash from the Blue Economy CRC, $265k cash from Carnegie

Sonardyne BlueComm to Live Stream Ocean Exploration

(ROV), which will also be fitted with BlueComm. The Triton submersible will stream its video to the ROV, which will in turn feed the data up to the REV Ocean research vessel via a cable. REV Ocean’s Triton 7500/3 is being built by Triton Submarines, builders of the first fully accredited (DNV/GL) submersible capable of diving to full ocean depth. The Triton’s unique pressure hull is being made of acrylic, which is over 300 mm (1 foot) thick and offers passengers a 360 degree and unobstructed view of the ocean during dives of up to 12 hours in duration. The design uses certified,

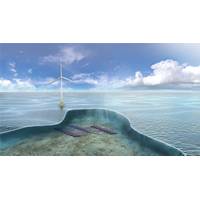

World's First: DNV Launches Floating Solar Power Recommended Practice

DNV, energy industry expertise and assurance provider on Wednesday published what it said was the world’s first recommended practice (RP) for floating solar power projects following a collaborative joint industry project (JIP) involving 24 industry participants."The Recommended Practice (DNVGL-RP-0584) will provide commonly recognized guidance based on a list of technical requirements for accelerating safe, sustainable and sound design, development, operation and decommissioning of floating solar photovoltaic (FPV) projects," DNV said.Floating solar power is a promising renewable

Tech File: COBRA Battery System Receives Class Certification

With DNV GL certification obtained in February 2021, the COBRA battery system from Becker Marine Systems can be used for a wide range of inland waterway and maritime shipping applications, and due to demand, Becker is expanding COBRA production at its Winsen (Luhe) location.Tailor-made for maritime, the COBRA system now has full certification including IEC 62619 and IEC 62620 and can now be installed on board inland waterway and ocean-going vessels. “We have achieved the highest standard of safety since our COBRA system also meets all safety requirements down to the level of the individual

Autonomy: Inside the Building of Ocean Infinity’s Armada Fleet

. “When looking at risk planning for the future of their business, future pandemics is now on everyone’s lists,” he says. “The risk of moving crews around the world and on and off of ships means uncrewed operations have definitely come to the fore.”The initial British flagged DNV GL class fleet is being built at the Grovfjord Mek. Verksted (GMV) yard in Norway. But Hook says future vessels are likely to also be built elsewhere and the company is already in talks with yards in the US, where they would be Jones Act compliant. The vessels have a hybrid-electric propulsion system

DNV GL Gives Nod for Heerema's Silent Offshore Installation Concepts

Heerema Marine Contractors' concepts for the silent installation of offshore facilities' foundations have received a Statement of Feasibility from the global quality assurance firm DNV GL.Heerema has been working on developing 'silent foundations' - pile foundations for offshore structures that can be installed without loud hammering. Hammering can be harmful to marine life and requires noise mitigation systems that produce a considerable CO2 footprint."The concepts being investigated are helical or screw piles and so-called push-in piles," Heerema explained.Heerema said

Putting Power on the Seabed: Edging towards a Subsea Powerhouse

enable entirely subsea developments to shore. The benefits are touted as a more scalable and flexible architecture.However, the much longer step-outs that have been targeted have bigger challenges, in terms of flow assurance, points out Bjørn Søgård, Segment Director, Subsea, at DNV GL. Potential candidate projects like Chevron’s Janz-Io subsea compression project, in 1300m water depth 200km offshore Australia, are targeting topside power and controls.Meanwhile, there’s also a growing move towards less simpler systems, which could provide a quicker win for less power-hungry

What's In Store for 2021? More Remote, More Data, More Autonomy

environment for many, with depressed oil prices having impacted the oil and gas industry specifically, resulting in a wave of company restructuring.“Companies are busier than ever working out what to prepare for the future,” says Bjørn Søgård, Segment Director for Subsea, DNV GL.Tier 1 contractors created through mergers just a few years ago are starting to be unravelled into more renewable versus traditional business (e.g. Aker Solutions spinning off its offshore wind and carbon capture segments) or demerging to distinguish upstream from midstream-downstream (e.g. TechnipFMC

Subsea Valve Actuator certified for Safety Integrity Level 3

The new concept for Subsea Valve Actuators (SVA) from Bosch Rexroth has been certified by DNV GL for application in safety systems with up to Safety Integrity Level (SIL) 3 requirements. The SVA is a self-contained actuator for opening and closing process valves in the deep sea at depths down to 3000 meters and deeper. The system consists of an electrically controlled drive with a hydrostatic transmission.The patent-protected SVA is design to open and close process valves for oil and gas production or in CO2 storage systems in deep sea applications. A redundant design, for example of the safety

August 2025

August 2025