Vatn Systems Launches New AUV and Rhode Island Manufacturing Facility

a strong competitive differentiation for us as we scale production capacity to 2,000+ vehicles annually to meet growing customer demand," said Brendan Smith, Director of Manufacturing at Vatn Systems.Vatn recently announced a partnership with Palantir that enables the company to digitize its manufacturing process and provide AI-driven insights to accelerate the production of AUVs built in the new facility, which is expected to reach full production capability in July 2025

Vatn Systems, Palantir Partner to Scale Manufacturing of AUVs for National Defense

, strengthening our ability to anticipate challenges, optimize resources, and deliver critical systems to our customers with unprecedented speed and precision," said Nelson Mills, co-founder and CEO of Vatn Systems.The partnership leverages Palantir's software platform to digitize the manufacturing process and provide AI-driven insights that will accelerate the production of underwater vehicles for national security applications. The collaboration will enable Vatn to streamline its Supply Chain Management and build additional resiliency."Vatn is building exactly the kind of mission-critical

ErectorCraft Launches First 3D-Printing Boat Hull Firm in US

ErectorBot LFAM HDPE systems, specialized engineering and production optimization, and the deployment of 3D concrete printing (3DCP) technologies for marine construction applications.ErectorCraft also provides training and technical support to help partners seamlessly adopt this next generation manufacturing process.“With its official launch, ErectorCraft is not just introducing a new way to build boats — it’s redefining what’s possible in marine manufacturing, bringing advanced technology to the water with real-world impact,” the company said

Aker Solutions Introduces Three Floating Wind Foundation Designs

an advanced steel floating substructure meticulously designed to provide a stable and efficient platform for wind turbines.The YFloat (Credit: Aker Solutions)Its symmetrical design facilitates efficient pre-fabrication with the option of local assembly, reducing material usage and simplifying the manufacturing process. The YFloat is said to offer scalability that facilitates higher power generation and reduced levelized cost of energy (LCOE).The CONFloat-Omega is a circular concrete floater concept featuring a moonpool at its center and an offset turbine and tower, specifically designed for harsh environmental

Teledyne Valeport Hosts Customer Open Day

Surface Vehicle (USV) provided by Maritime Robotics AS. The setup also included the Valeport SWiFT SVP, highlighting the seamless integration of solutions for hydrographic and oceanographic surveying.Attendees were treated to a guided factory tour, providing an inside look at Valeport's manufacturing process and the precision engineering behind its respected marine instruments. The day also included technical talks, allowing customers to deepen their understanding of how Teledyne Valeport’s innovative equipment works together to provide comprehensive solutions for the marine industry.Guy

New Product: Balmoral Seamless Bend Stiffener Connector

and efficiency.“By enabling a seamless fusion of dynamic bend stiffeners with offshore structures our commitment to pioneering engineering solutions for the offshore energy sector is again demonstrated.”Diverless installation lies at the heart of this innovation while the design and manufacturing process adheres to API 17L standards. This commitment to operational efficiency is further highlighted by the incorporation of a reusable pull head which not only enhances installation timelines but also adds practicality to the overall process, the company said.The full system consists of a lead-in

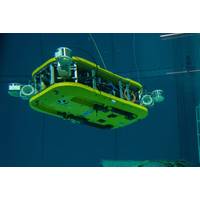

Tech File: Dual-Arm AUV Emerges from German Consortium

ControlWITTENSTEIN cyber motor GmbH developed and produced the highly robust thruster drives for the AUV's locomotion. These have a thrust of up to 500 newtons, are protected against seawater and are suitable for water depths of up to 6000 meters. No liquid fillers were used in the manufacturing process, which employed special potting technologies to avert chemical hazards to the environment. The servo inverters that go with the thrusters include sensorless control specifically matched to the thruster motor, providing accurate, highly dynamic speed control over the entire speed range up

Valeport Achieves 'Made In Britain' Status

and maintaining production here in the UK," said Matt Quartley, Valeport managing director. "We also believe it highlights the quality of our products and expertise gained from over 50 years of British manufacturing expertise.”Valeport retains all aspects of developing and manufacturing processes in-house, an approach which means they have total control over every stage of the manufacturing process and can guarantee the quality and consistency of their products. The company’s riverside premises house all the facilities for designing, CNC machining, environmental testing, assembly

Unique Floating Wind Turbine Set for Middle East Debut

the mainland storage facility, the water is fed into the water distribution system of the community," SIP explained. Below are the project partners, and their respective responsibilities, as shared by SIP:Technology & Project Development: SYNLIFT Industrial Products (Germany)Plant Manufacturing / Process: thyssenkrupp Industrial Solutions (Germany)Plant Manufacturing / Marine: CRIST Shipyard (Poland)Technology Partners (Components):Submarine Cabling: NSW / Prysmian Group (Germany)Fine Filtration: Boll & Kirch Filterbau (Germany)Technology Partners: (Services):Wind Turbine Design:

August 2025

August 2025