Saipem Upgrades UPS’ Pipeline Tech for Offshore and Subsea Use

Italian offshore energy services firm Saipem has secured DNV’s Statement of Qualified Technology for pipeline technology developed by United Pipeline Systems, which was upgraded for offshore and subsea use.The technology was initially developed for the internal lining onshore pipelines before Saipem conducted upgrades to make it suitable for offshore and subsea use.It uses plastic as a replacement for corrosion-resistant alloys in the inner coating of pipelines, thus reducing the total system cost by up to 40%, Saipem said.According to the Italian company, DNV's certification grants its

InterMoor Delivers Mooring Piles for LLOG’s Salamanca FPU

discoveries in the U.S. Gulf of Mexico.It said at the time that the Salamanca is comprised of a ‘uniquely’ designed FPU that will be created from the refurbishment of a former Gulf of Mexico production facility that was previously decommissioned.The subsea development will consist of two pipeline systems for the Leon field, located in Keathley Canyon 686, and one pipeline system for the Castile field, located in Keathley Canyon 736. The infield pipelines will produce and flow from wellsite PLETs to the Salamanca floating production facility (FPS).LLOG Hires ABL for Marine Warranty Services at

LLOG Taps ABL for Marine Warranty Services at Salamanca Project in Gulf of Mexico

subsea development of the Salamanca project in the U.S. Gulf of Mexico.The Salamanca development project envisages the build-out of the Leon and Castille oil fields in water depths ranging from 1,800 to 2,000 meters.The subsea portion of the project includes the installation of three infield subsea pipeline systems, as well as the design and fabrication of subsea structures. The pipelines will run from the wellsite to the Salamanca floating production facility.Under the terms of the contract, ABL will provide technical document review and approval of all project critical procedures, drawings and documentation

Hydrogen Pipelines: DNV Launches Phase 2 of H2Pipe Project

; DNV said.DNV said that industry players were exploring ways of transporting hydrogen as an additive or replacement for natural gas, but "currently, offshore pipeline codes insufficiently cover the transport of hydrogen or hydrogen blends by offshore pipelines."The DNV standard for subsea pipeline systems (DNV-ST-F101) includes hydrogen as a listed transport product, but additional considerations are required to meet the target safety level for an increased use of hydrogen. A special concern in this respect, according to DNV, is the potential detrimental influence of hydrogen on resistance

Carbon Capture & Storage: A New Lease of Life for Submarine Pipelines?

, project manager on the project. “For C-Mn steel pipelines, components and associated welds, it is well recognized that hydrogen may promote hydrogen embrittlement which could have an adverse effect on the pipeline system integrity, and hence impacting both the design and operation of such pipeline systems. There are still uncertainties related to how hydrogen gas or blends may affect the mechanical properties of these materials.”A first revision was shared in December 2021, but there are still uncertainties around how hydrogen gas or gas blends may affect mechanical properties of pipelines

Busy Summer for Pipeline Tech Firm STATS Group

pipeline isolation projects in its 23- year history.STATS said that it had, during the 2021 summer shutdown season, supported six separate Tecno Plug isolation deployments in the UK North Sea, on pipelines ranging from 20” to 36” in diameter. "The projects were on critical pipeline systems on behalf of multiple clients, with the isolation periods ranging from 10 to 45 days," the company said.Isolation activities were carried out onshore and offshore at various locations and included the use of STATS Remote Monitoring System, which allowed Tecno Plug isolation tools to be

Swire Seabed Orders a HUGIN AUV

;s CEO Arvid Pettersen explained. “We believe that the future of inspections and subsea survey is indeed autonomous and we are excited to be at the forefront of an evolving industry.”In October 2018, Swire Seabed completed its first commercial autonomous inspection of offshore pipeline systems for Equinor using Kongsberg Maritime’s HUGIN AUV and, shortly after in December 2018, was awarded a frame agreement with Equinor for provision of offshore survey services.Now, the firm will have a HUGIN AUV of its own. Due for delivery in 2020, the vehicle will be rated to 4,500 meters

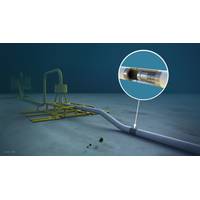

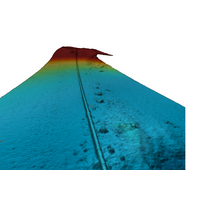

Autonomous Subsea Pipeline Inspection

Swire Seabed said it completed autonomous inspection of offshore pipeline systems for Equinor in October 2018 utilizing Kongsberg Maritime’s Hugin autonomous underwater vehicle (AUV).The inspections were performed on three pipelines between Kollsnes and Troll A. In total, 180 kilometers of pipeline were inspected over two AUV dives.The inspections were undertaken with the subsea vehicle in autonomous mode, with a small surface vessel accompanying the AUV to provide positional updates to the vehicle and act as a communications relay between the AUV and the Control Center at Swire Seabed’s

Project to Standardize Subsea Processing Progressing

the vendors and oil companies, which will enable the future large-scale use of subsea boosting.” Morgan Harland, General Manager, Subsea & Pipelines, Woodside, said, “Through innovation and collaboration, Woodside aims to deliver outstanding performance of our subsea and pipeline systems throughout the entire lifecycle. The standardization of subsea processing JIP and its initial focus on subsea pumping hits the mark with standardized guidelines being developed for subsea processing modules and interfaces that are efficient, reliable and readily installed and serviced. We use

February 2025

February 2025