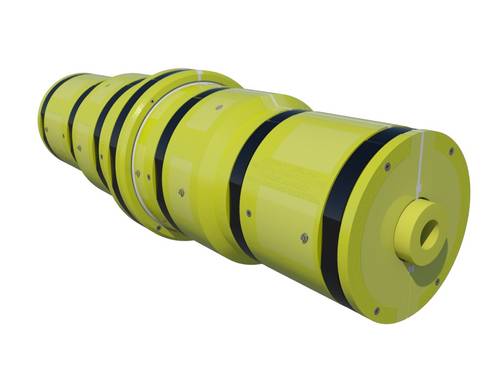

Flowline Insulation Covers Tackle Extreme Temps

Press release- Trelleborg’s offshore operation has engineered a new insulation cover that withstands extremely cold temperatures at subsea depths and also, with the combination of a silicone liner, the extreme temperatures of hot hydrocarbons.

The insulation cover achieves the highest temperatures yet accomplished and in addition, is lighter than steel covers; not molded directly to the pipe the cover gives easy access to critical parts of the flow stream.

Ben Wait, Customer Group Manager for Trelleborg’s offshore operation, said, “The new insulation covers are made from a combination of our trusted insulation systems including silicone Vikotherm S1 and polyurethane Vikotherm P7. They utilize the properties of cast systems which are poured in a liquid form and solidify to create the finished ‘jacket’, unique to the application."

As the polyurethane and silicone used in the insulation cover has previously been qualified, time to market was reduced, meaning that it was quickly ready for use by our customers.

August 2025

August 2025