Pipetech Wins Project with Nexen

Pipetech, the independent process system integrity specialist, has won a project with operator Nexen to deliver Active Caisson Management on its Scott platform.

Active Caisson Management delivers a single sourced solution for inspection, cleaning, coating and planned and programmed maintenance and repair scheduling to drive cost efficiencies and maintain asset integrity throughout the lifecycle of a caisson.

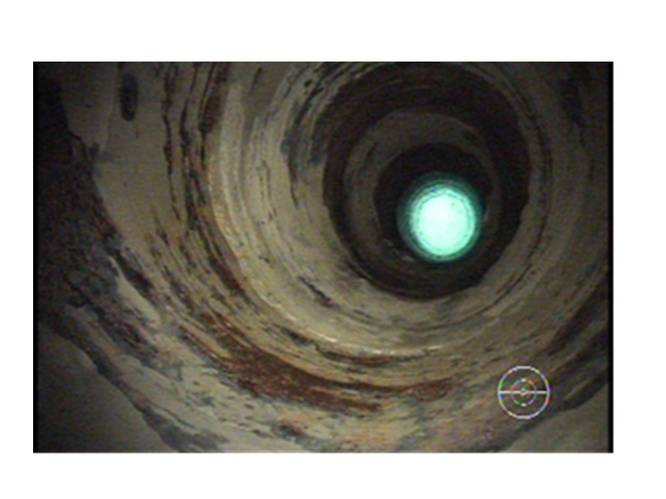

Pipetech has completed the first stage to remove internal scale build up from a 42 inch produced water caisson on the platform, located 188km from Aberdeen, while it remained in operation. The scope also includes ongoing inspection and monitoring.

Eric Doyle, managing director at Pipetech, said, “This project is a fantastic example of our ability to mobilize quickly and remove stubborn scale which has been problematic to tackle. By carrying out the work while the platform remained in operation, we saved the valuable cost implications of shutting down production as well as a lengthy start up process.

“With our many years of caisson experience, we understand the importance of a proactive integrity management plan. Our Active Caisson Management service means we will continue to manage inspection on the Scott platform to monitor the caisson’s internal scale levels and intervene if required. This proactive approach is vital in today’s cost-effective market.”

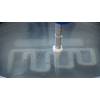

Following a site survey to identify the full requirements, Pipetech deployed a team of four to carry out the clean utilizing its Aqua Milling technology. The system has a proven track record in successfully removing the toughest of scale and blockages which other systems struggle with and has the ability to reach up to 600 meters in a straight line from a single point of entry. It can negotiate up to 20 directional changes. Pipetech is currently the only company licensed to use Aqua Milling in the U.K.

The Aqua Milling technology was deployed 27 meters above sea level and recovered back to the 1.5 inch entry point, mitigating any chance of blockages. In total, the project took eight days to complete with a full camera inspection conducted during a planned outage to further confirm the results of the cleaning.

December 2025

December 2025