The global economic outlook is uncertain; this uncertainty is leading to depressed investment worldwide, particularly in energy and mining activity. The international ports and terminals sector forms an important part of the infrastructure supporting these activities. As the sector is exposed to restraints on investment, the emphasis is on reducing in operating cost. HR Wallingford advises clients on how their activities interface with the water environment. So how are we playing our part in helping clients reduce the costs of their port and terminal operations? Tom Matthewson and Iain Gunn explain how we help our clients to reduce costs by optimising the port operations cycle and their dredging activity.

Optimizing Port Operations

Managing a port or terminal’s operability is critical to reducing the unit costs of running a port. Many of the factors involved relate to the marine environment, and a good understanding of these factors can be used to reduce a port’s operating costs. Simulation of the port cycle, including ship arrival/ departure, cargo transfer, onshore storage capacity and logistics along with the influence of metocean conditions can be used to improve efficiency and reduce the cost of the port operation.

Port operations simulations involve representing individual terminal components, such as vessel arrivals, cargo handling, allocation of resources (pilots, tugs, berths, equipment, labour etc.) within an interconnected system to simulate the performance of the overall port operation while incorporating historical or forecast weather conditions and their influence on the operation.

These studies provide supporting evidence to operators when; assessing terminal downtime and storage requirements; evaluating planned changes to terminal operating procedures; identifying bottlenecks and constraints on operations; and undertaking economic comparisons of conceptual designs.

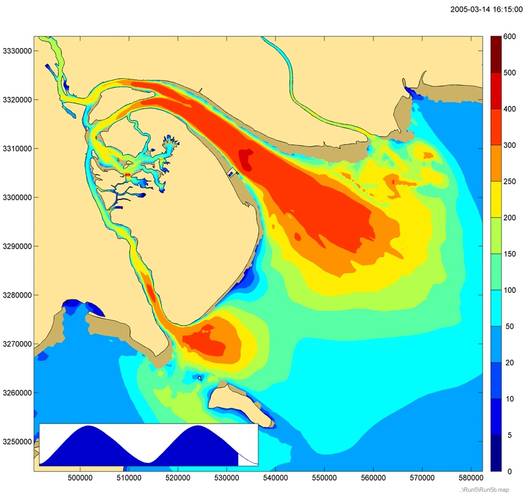

Reducing the Costs of Maintenance Dredging

Dredging to maintain a port or terminal’s navigation often presents opportunities to reduce costs. When examining dredging practices, we generally look at both the nature of the siltation problem, and the dredging methods employed. Port operators face the dilemma of programing their dredging procurement to maintain the required depth of navigation, but not to the extent that the channel is over-dredged and the dredging problem increased. Channel sedimentation is affected by factors such as geomorphology and tides but also seasonal factors, and can be minimised through careful channel design.

As well as understanding the nature of port sedimentation, it is also important to establish that the most cost-effective dredging methods being employed. HR Wallingford has successfully advised clients on how to reduce their dredging costs by adopting more efficient dredging practices such as water injection and side casting systems.

Minimizing the Need for new Investment

There are also cases where, with careful examination, it may be possible to avoid or reduce investment in new structurers or dredging and still permit larger vessel to access a port or terminal. This could be through close examination of vessel arrival and departure navigation, using simulation tools. Alternatively, it may be possible to demonstrate that a layer of fluid mud would not in fact impede safe access to a terminal.

The Authors

Tom Matthewson is a Technical Director and Business Manager at HR Wallingford, leading the development and delivery of multidisciplinary marine studies, principally related to ports and coastal infrastructure projects. He has over 20 years’ experience in the technical direction and management of marine environmental assessment studies for a wide range of projects and programmes, with a track-record in major projects.

Iain Gunn is a Technical Director and Business Manager at HR Wallingford with a focus on the development and delivery of multidisciplinary marine studies, principally related to oil and gas infrastructure projects . Iain has over 20 years’ experience in the planning and execution of multidisciplinary engineering studies in the marine environment.

August 2025

August 2025