Self-compensating Magnetometer for Gavia AUV

OFG self-compensating magnetometer (SCM) added to Teledyne Gavia sensor suite

Teledyne Gavia, manufacturer of the Gavia autonomous underwater vehicle (AUV), has completed trials of the AUV self-compensating magnetometer (SCM) from Ocean Floor Geophysics (OFG).

Now, following successful integration and field trials in Iceland, the sensor system is being offered as part of the expanding suite of tools available to Gavia AUV users.

CEO of OFG, Matthew Kowalczyk elaborated on the principal advantage of the SCM system: “There are many magnetometer technologies available on the market. The requirement that drove the development of the SCM system was to remove the need to tow a magnetometer, which is problematic in many AUV operations.”

Kowalczyk continued, “The SCM can be integrated inside the body of the AUV or simply strapped to the hull of the AUV and compensates for the magnetic signature and motor currents of the AUV. This results in a system that does not have to be mounted on a pole, does not have to be towed behind the AUV or put into a de-gaussed hull section. Not only does this simplify integration into new vehicles, but opens up opportunities for simple retrofits for existing AUVs regardless of the sensor/battery/hull configurations that they have. You can even change the vehicle configuration and magnetic signature between missions, e.g. adding or removing sensors, and the SCM will still work as the compensation coefficients are calculated at the beginning of each mission.”

OFG said its SCM systems are being used for AUVs around world on various applications ranging from geological mapping, mine-countermeasures, and vessel signatures, to unexploded ordnance (UXO) and marine archaeology.

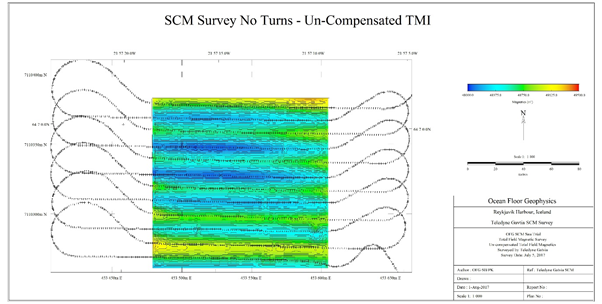

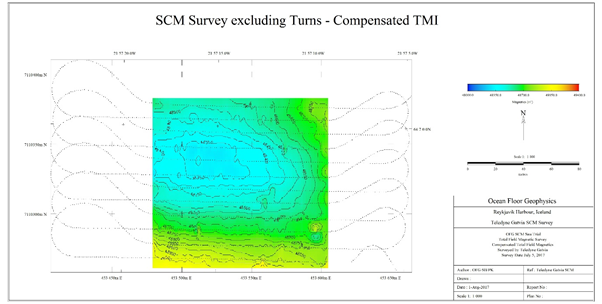

Equipping the Gavia with the OFG SCM system for AUVs enables the collection of real-time compensated data that removes the magnetic signature of the AUV ensuring that the ambient field is being measured rather than the AUV itself. Combining the compensated three-vector magnetic data of the SCM with other sensors such as side scan imagery, bathymetric survey data, sub-bottom profiler data, and water chemistry sensors further increases the value of AUV data.

“Teledyne Marine strives to provide our customers with a variety of technical solutions to meet their operational requirements. The integration and testing of the OFG Magnetometer has yielded good results and will be a valuable option for current and future Teledyne Gavia and SeaRaptor AUV users,” said Arnar Steingrimsson, Director Strategic Business Development AUVs, Teledyne Marine.

February 2025

February 2025